Battery Solutions for

Heated Apparel

Engineered battery systems designed specifically for wearable heated apparel, balancing power output, comfort, safety, and long-term reliability at the system level.

More Than Just a Battery Pack

A battery solution for heated apparel is a system-level power architecture, not a standalone battery pack.

It is designed to deliver stable thermal output while accounting for wearability, safety protection, and regulatory requirements.

System Components

- Customized Battery Management System (BMS)

- Ergonomic Housing Design

- User Interface & Control Integration

- Thermal Regulation Logic

- Connector & Cabling Architecture

- Environmental Protection (Water/Impact)

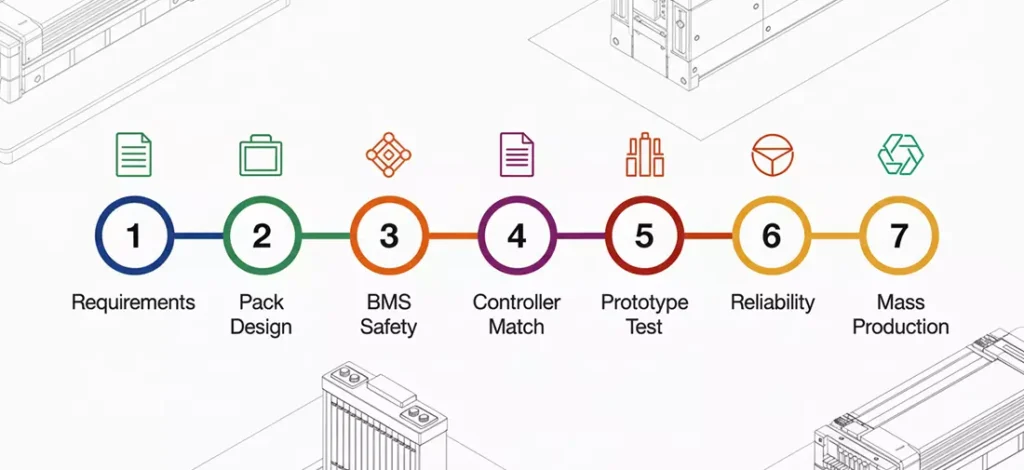

End-to-End Engineering Capabilities

Reliable battery performance in heated apparel depends on engineering control across the entire battery lifecycle, from architecture design to validation and production.

Requirement mapping: heating power, runtime targets, garment constraints, market requirements

BMS & protection design: safety thresholds and fault handling

Controller matching: output stability, heat-level logic, UX requirements

Prototype build & validation: basic electrical checks, thermal behavior, connector reliability

Reliability screening: aging, vibration/handling simulation (only list what you actually do)

Pilot run to mass production: consistency controls and incoming/outgoing inspection

Cell & pack architecture: voltage/capacity selection, parallel/series design, enclosure constraints

Battery Solutions by Application

Application

Voltage System

Capacity Range

Key Requirement

Heated Gloves

3.7V / 7.4V

2000mAh - 3000mAh

Compact size, curved form factor for comfort

Heated Socks / Insoles

3.7V

2200mAh - 4000mAh

Ultra-slim profile, remote control integration

Heated Jackets / Vests

5V (USB) / 7.4V / 12V

5000mAh - 10000mAh

High output for multi-zone heating, USB-C PD

Base Layers

7.4V

2200mAh - 4000mAh

Lightweight, washability protection

Industrial Workwear

12V / 24V

5000mAh - 20000mAh

Ruggedized casing, extended runtime, impact resistance

Safety & Compliance Built-In

Battery safety in heated apparel is not an add-on feature, but a design constraint defined at the system level.

Multi-Level Protection

- Over-charge & Over-discharge Protection

- Short Circuit Prevention Logic

- NTC Thermal Monitoring & Cut-off

- Cell Balancing for Pack Longevity

- Redundant Safety Circuits

Compliance Readiness

Our designs are pre-validated to meet stringent international standards, streamlining your certification process.

RoHS

FCC

UL 2054

UN 38.3

IEC 62133

Comfort, Wearability & Industrial Design

In wearable heated apparel, battery form factor decisions directly influence pressure points, mobility, and long-term wearing comfort.. We focus on the “wearability” of power, ensuring that the battery integrates naturally with the garment without causing discomfort or restricting movement.

By utilizing curved cell technology and slim-profile housings, we create battery packs that contour to the body. Weight distribution is optimized to prevent sagging or imbalance in the apparel.

Our industrial design team considers tactile feedback, button placement, and visual indicators to ensure the user interface is intuitive, even when wearing gloves.

OEM & ODM Battery Solution Support

OEM and ODM battery solution support focuses on reducing development risk while ensuring system compatibility and production consistency.

OEM Services

Manufacturing based on your existing specifications and designs.

- Build-to-print manufacturing

- Cost-down engineering analysis

- Supply chain consolidation

OEM Services

Manufacturing based on your existing specifications and designs.

- Build-to-print manufacturing

- Cost-down engineering analysis

- Supply chain consolidation

Battery System Matching Logic

A common failure point in heated apparel is the mismatch between the battery’s output characteristics and the heating element’s requirements. Using an off-the-shelf power bank with a specialized heating system often leads to poor performance or safety risks.

Improper matching can result in rapid voltage sag, premature cutoff, or overheating of the connector terminals. Our system-level approach ensures that the battery’s discharge curve is perfectly aligned with the load profile of the heating elements, guaranteeing consistent warmth and maximizing runtime.

Battery Knowledge Center

Choosing the right battery voltage is critical for heated clothing performance and safety. This article compares 7.4V and 12V battery systems, explaining how voltage influences heating efficiency, runtime, comfort, and garment design. Written from an engineering perspective, it helps brands and OEMs make informed battery decisions for different heated apparel applications.

Battery performance plays a critical role in how heated apparel actually feels and functions in real use. This article explains how battery technology—beyond voltage and capacity—affects heating stability, runtime consistency, safety, and user comfort. Written from an engineering perspective, it helps brands and OEMs understand why battery design choices directly shape heated apparel performance.

Lithium-ion and lithium-polymer batteries are both used in heated clothing, but they deliver very different real-world results. This article compares the two battery chemistries from an engineering perspective, explaining how they affect heating stability, safety, form factor, and garment design. It helps OEMs and brands choose the right battery chemistry for different heated apparel applications.

Battery capacity plays a major role in how heated apparel performs and feels in daily use. This article explains how to choose the right battery capacity for heated gloves, jackets, and socks, focusing on runtime expectations, wear comfort, and system efficiency. Written from an engineering perspective, it helps brands and OEMs avoid common capacity selection mistakes in heated clothing design.