PCBA Design for Heated Wearables & Smart Heating Systems

We design heating controller PCBAs and power-protection electronics for heated insoles, socks, gloves, vests, and jackets—from concept to prototype validation and production-ready handoff.

- Heating control + temperature sensing + safety protection

- Prototype bring-up, functional validation, and DFM support

- OEM/ODM-ready for wearable heating products

What We Design (PCBA Scope )

Our PCBA design service is built around real-world heated wearable use cases: stable temperature control, repeatable heating levels, and robust protection for daily use and outdoor environments.

- Heating controller PCBA (multi-level control, NTC/temperature sensing, PWM control)

- Power & protection (over-current, over-temperature, short-circuit protection)

- Battery-related electronics (BMS/protection integration when required)

- Remote / app-ready control interfaces (project-dependent)

- Production handoff support (BOM, Gerber, and test guidance)

Why PCBA Design Matters for Heated Wearables

Stable heating, not just “high power”

Good control design helps maintain comfortable warmth and reduces hot spots across different materials and ambient temperatures.

Safety protection is non-negotiable

Protection design helps prevent overheating and abnormal current scenarios in real use.

Lower returns through consistency

Design-for-test and production-ready verification improves consistency across batches.

Faster path to market

A clear prototype-to-production workflow reduces iteration time and avoids late-stage surprises.

Our PCBA Development Process

- Requirements review: product type, target heat levels, runtime, battery capacity, target market.

- Architecture proposal: block diagram, key components, protection strategy.

- Schematic & PCB layout: DFM considerations for reliable mass production.

- Prototype bring-up: debugging, firmware/interface integration (if applicable).

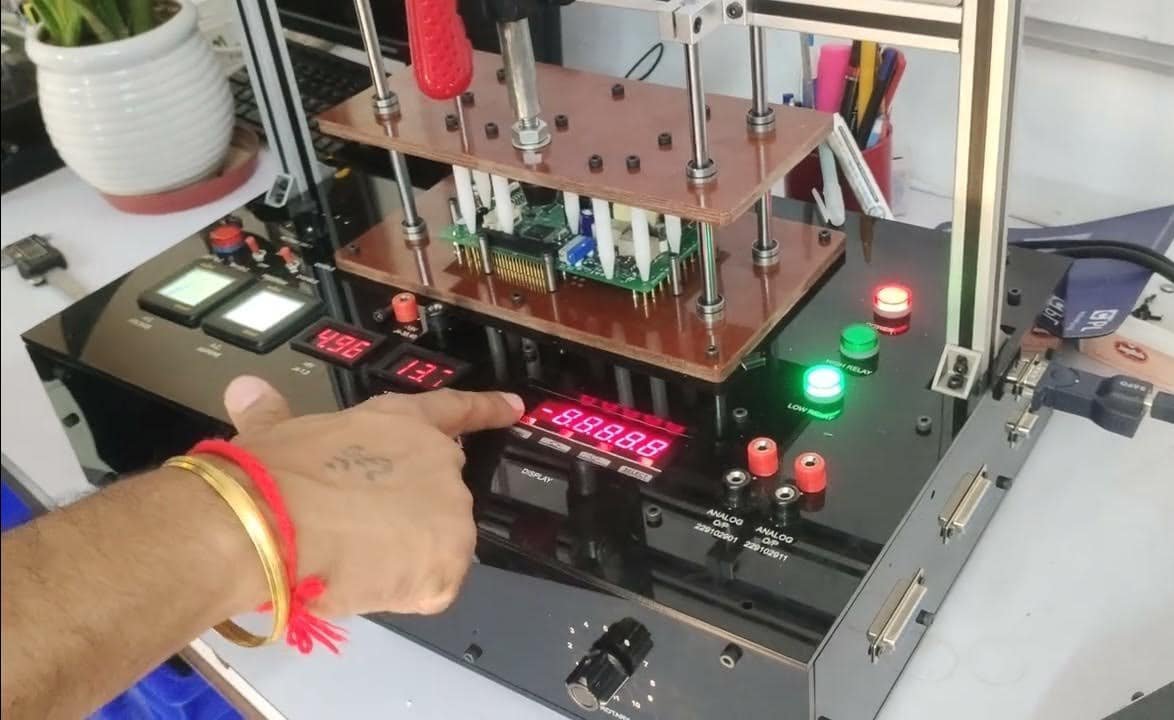

- Validation testing: functional, thermal, endurance and protection checks (project-dependent).

- Pilot run: small batch verification, yield feedback, process refinement.

- Mass production support: test guidance, inspection checkpoints, traceability approach.

Testing & Quality Controls

For heated wearables, testing is where design decisions become measurable results. We focus on practical verification that supports safe, repeatable performance.

- Incoming inspection for key electronic components

- Functional verification of heating levels and control response

- Protection checks (over-temperature / over-current / short-circuit scenarios )

- Batch consistency support with production test guidance

Built for Complete Heating System Integration

We design PCBAs with the full system in mind—controller behavior, battery protection, connectors, and heating elements—so performance stays consistent after the product is assembled and worn.

- Controller + battery pack compatibility considerations

- Connector and cable routing considerations for wearables

- Heat-level logic aligned with real user scenarios

PCBA Design FAQ

Do you support both PCBA design and mass production?

Yes. We can support the workflow from design and prototype validation to production handoff and manufacturing coordination (project-dependent ).

What products do you typically design PCBAs for?

Heated insoles, socks, gloves, vests, jackets, and other wearable heating systems that require stable control and protection.

Can you integrate remote control or app features?

We can evaluate remote/app-ready control options based on your target user experience, cost targets, and compliance requirements.

What information do you need to start a project?

Target product type, heat levels, runtime goal, battery capacity, heating element type, target market, and any required certifications.

Request a PCBA Design Consultation

Share your product type, target runtime, heat levels, battery capacity, and target market. Our team will reply with a practical proposal.