Heating Element Design for Wearable Heating Systems

Engineering high-performance heating elements for safety, durability, and comfort in wearable electric heating products.

- Electrical & thermal system design

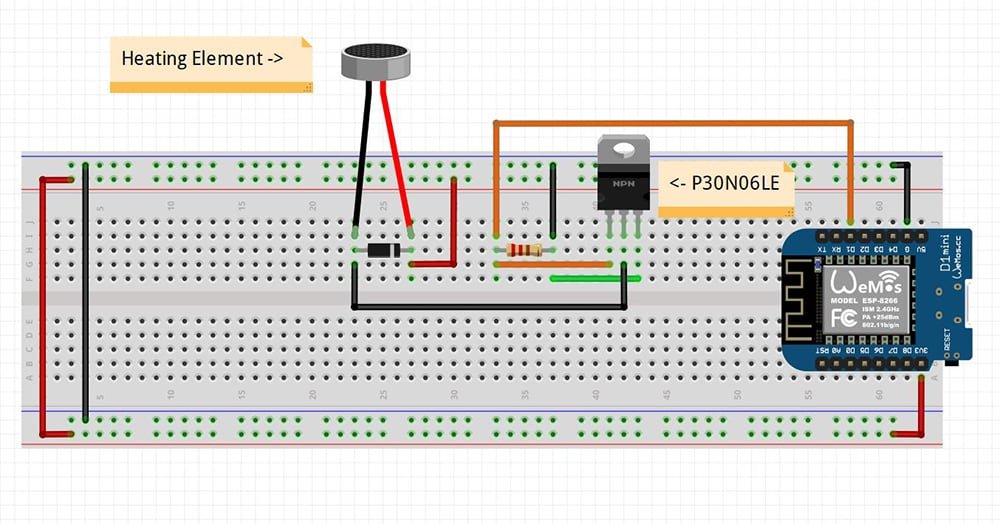

- Integration with PCBA and temperature control

- Washability, safety, and long-term reliability

- OEM & ODM engineering support

What Is Heating Element Design?

Heating element design is the engineering process of defining how a wearable heating element generates heat, distributes warmth across the body, and remains stable under real-world conditions. In wearable systems, the element must work safely near skin contact while enduring continuous bending, moisture exposure, and repeated thermal cycles.

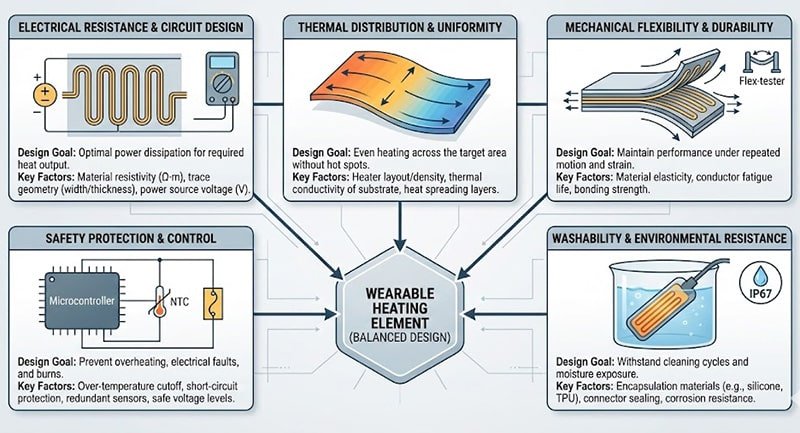

A reliable design is not just "choosing a better material." It is a system-level decision that connects electrical resistance, thermal distribution, insulation strategy, wiring and connectors, and how the element interacts with batteries, PCBA control logic, and protective circuits.

Done properly, heating element design delivers consistent warmth, comfortable heat uniformity, long-term durability, and predictable safety behavior under faults.

Key Design Dimensions in Wearable Heating Elements

Wearable heating performance is shaped by multiple design dimensions that interact with each other. Optimizing one dimension in isolation often creates risk in another. The table below summarizes the engineering dimensions that define performance, comfort, and safety.

| Design Dimension | What It Affects |

|---|---|

| Electrical resistance | Power output, current draw, battery compatibility, runtime |

| Heating element layout | Heat uniformity, hot-spot control, comfort, perceived quality |

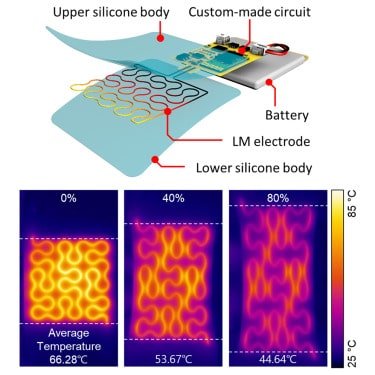

| Material & structure | Flexibility, durability, strain tolerance, connection stability |

| Temperature control strategy | Thermal stability, response time, comfort tuning, safety behavior |

| Washability | Moisture resistance, insulation integrity, long-term reliability |

| Protection systems | Over-temperature safety, fault response, burn and recall risk reduction |

System-Level Engineering, Not Component Selection

Many wearable heating problems do not come from "bad materials"—they come from mismatches between the heating element and the rest of the system. In practice, instability appears when electrical behavior, thermal behavior, and mechanical constraints are not engineered together.

- Resistance vs. battery platform: incorrect matching can cause overcurrent, weak heating, or unstable output.

- Layout vs. sensing location: sensors may not represent the hottest zone, leading to delayed protection.

- Power vs. insulation: trapped heat can raise local temperatures even when average power looks acceptable.

- Flexibility vs. connections: repeated bending can introduce resistance drift or intermittent faults.

A robust wearable heating element is designed as part of a unified architecture: battery → PCBA control → heating element → temperature feedback → protection response. This systems approach is the foundation for comfort, safety, and long-term reliability.

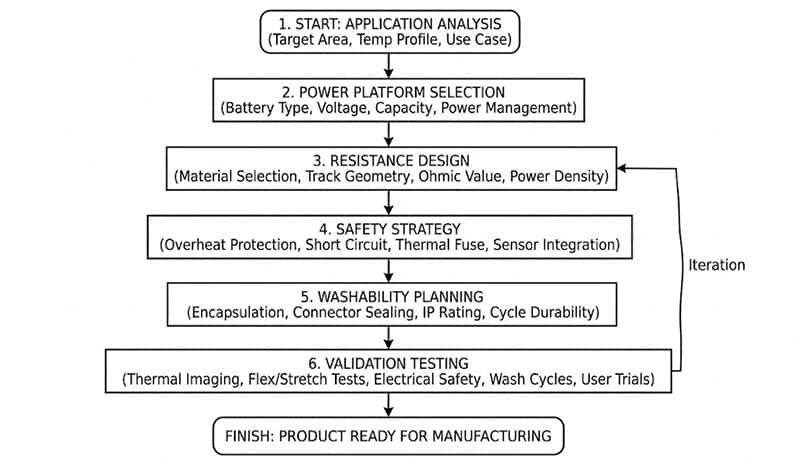

Our Heating Element Design Process

Heating element design is executed through a structured engineering workflow that prioritizes predictable system behavior under real wearing conditions. The goal is to define performance and safety at the design stage—before mass production.

- Application analysis: temperature environment, activity intensity, wear time, garment structure.

- Power platform definition: battery voltage, capacity, discharge characteristics, connectors.

- Resistance & pattern design: target power, heating zones, routing, and comfort tuning.

- Control & protection strategy: sensing method, thresholds, cutoffs, fault states.

- Mechanical & insulation design: strain relief, encapsulation, moisture barriers.

- Validation & reliability testing: stability, durability, wash cycles, safety verification.

In-Depth Engineering Topics

The articles below expand each design dimension with deeper engineering logic and testing considerations. Together, they form a structured knowledge cluster that supports heating element design decisions.

Electrical & Control

Structure & Durability

Why Heating Element Design Capability Matters

For OEMs and product developers, design quality directly affects safety risk, field reliability, and user experience. Most avoidable failures are introduced early—when resistance targets, layout decisions, sensor strategy, and protection thresholds are not aligned.

- Safety & compliance risk: overheating and fault behavior must be predictable.

- Warranty & returns: durability issues often appear after real bending and wash cycles.

- Comfort & perceived quality: uniform warmth matters more than peak temperature.

- Brand credibility: stable heating performance builds trust across seasons.

Heating Element Design Is the Foundation of Wearable Heating Products

Wearable heating elements must be engineered for real conditions: variable power, movement, moisture, insulation effects, and strict safety expectations. Consistent warmth, comfort, and long service life are outcomes of system-level design—not isolated component choices.

By approaching heating element design as a unified architecture (electrical + thermal + mechanical + safety ), wearable heating products achieve stable performance and predictable safety behavior across their lifecycle.