Custom Mold Development for Heated Apparel & Accessories

Turn your heating product concept into reality with our in-house mold design, tooling, and prototyping services. From initial 3D modeling to full-scale production, we handle every step with precision and speed.

- 8-member in-house R&D team with heating system expertise

- 20+ years of mold design & manufacturing experience

- Complete tooling capabilities: injection, compression, and soft goods

- Fast turnaround: CAD approval to first sample in 15–25 days

What Is Mold Development for Heated Products?

Mold development is the process of designing and manufacturing custom tooling to produce heated apparel components—such as glove shells, insole bases, jacket pockets, battery housings, and controller casings—that fit your brand's unique specifications.

For ODM clients, off-the-shelf molds limit design freedom. Custom molds allow you to differentiate your product with unique shapes, materials, heating zones, integrated branding, and proprietary features that set your product apart in competitive markets.

At Dr. Warm, we don't just build molds—we integrate mold design with heating circuit layout, battery housing engineering, and thermal performance testing. This ensures your product is manufacturable, safe, and optimized for cost-efficiency from day one.

Since 2013, our 8-member R&D team has designed over 150 custom molds for heated gloves, insoles, jackets, vests, and accessories, serving brands in North America, Europe, and Asia-Pacific.

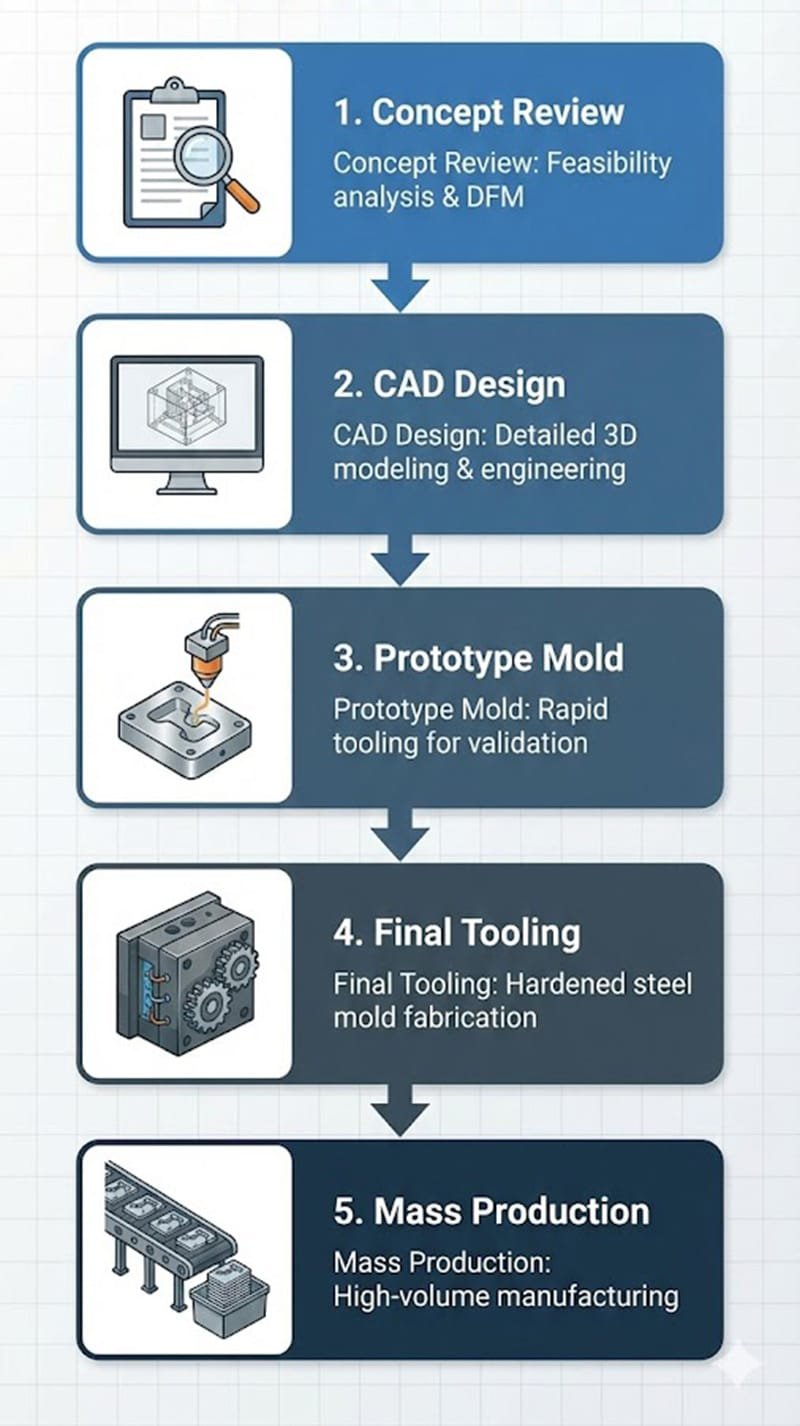

Our Mold Development Process

We follow a transparent, step-by-step workflow to turn your concept into a production-ready mold—with clear deliverables at every stage.

Step 1: Concept & Requirements Review

You share your product idea, target specifications, material preferences, heating requirements, and budget. Our engineers assess technical feasibility, suggest design improvements based on manufacturing best practices, and provide an initial cost estimate and timeline.

Deliverable: Technical feasibility report + preliminary project timeline

Step 2: 3D CAD Design & Simulation

Our design team creates detailed 3D models using professional CAD software (SolidWorks, AutoCAD ). We simulate heating element placement, thermal distribution, structural integrity, and assembly processes to identify potential issues before fabrication begins.

Deliverable: Editable CAD files for your review and approval (STP, IGES, or DWG format)

Step 3: Prototype Mold & Sample Production

We fabricate a prototype mold—using aluminum tooling or 3D-printed components depending on complexity—and produce 5 to 10 functional samples. These samples undergo rigorous testing: heating performance validation, fit checks, durability stress tests, and battery life measurements.

Deliverable: Physical samples + test data report (temperature curves, power consumption, cycle testing results )

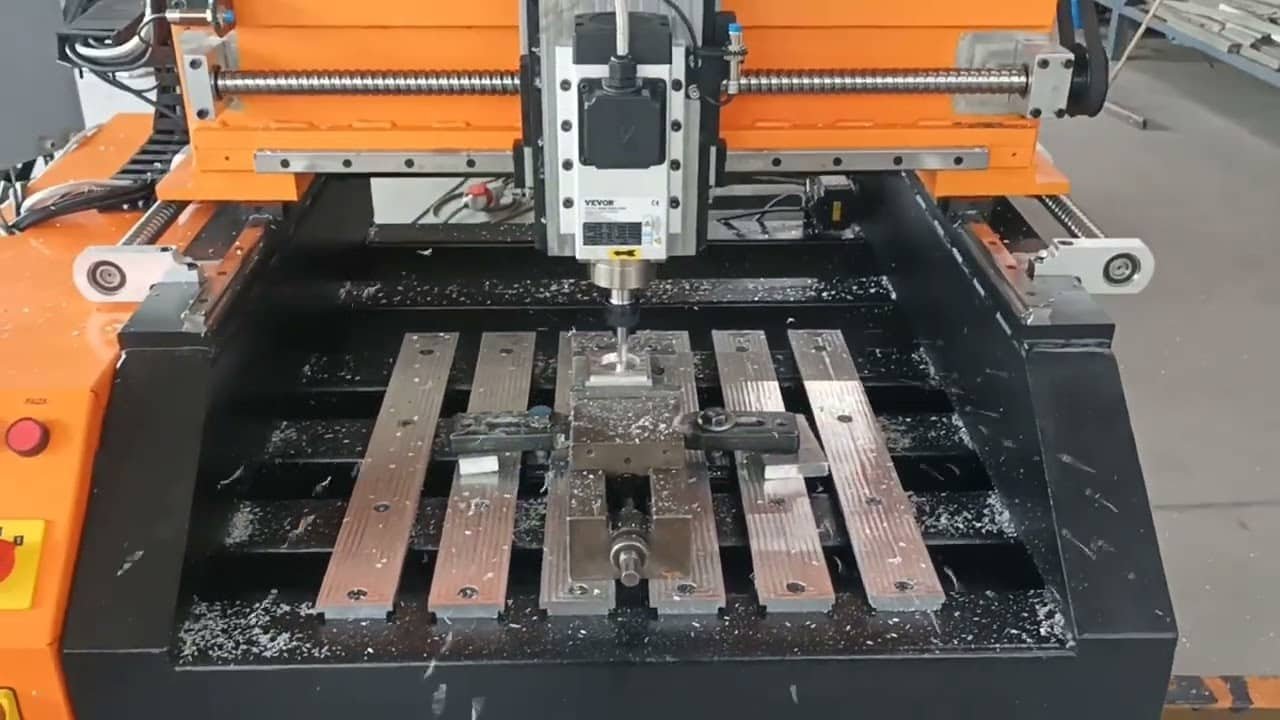

Step 4: Mold Refinement & Final Tooling

Based on your feedback, we refine the design and move to production-grade steel tooling. The final mold undergoes precision quality checks—dimensional accuracy verification, injection pressure testing, and surface finish inspection—to ensure it meets our ISO9001 standards.

Deliverable: Production-ready mold with guaranteed lifespan (50,000–500,000 shots depending on material and usage )

Step 5: Trial Run & Mass Production Approval

We run a small trial batch (typically 50–200 units) to verify consistency, quality, production efficiency, and heating system reliability. Once you approve the trial samples, we proceed to full-scale manufacturing with locked-in specifications.

Deliverable: Approved production samples + confirmed production schedule