Product Design & Engineering For Heated Wearables

Turn a concept into a production-ready heated product—built for stable warmth, safe power management, and repeatable manufacturing.

- Heating system design: zones, power budget, and control logic.

- Electronics support: controllers, protection features, and integration.

- Prototype fast, validate reliability, then scale to mass production.

- Experience across heated insoles, socks, gloves, vests, and jackets.

Who This Service Is For

If you're launching a heated-wearable line and need more than assembly, our engineering team helps you move from concept to scalable production with fewer surprises. We work best with teams that value clear requirements, fast iteration, and measurable validation before mass production.

Outdoor & Winter Sports Brands

Develop heated gear for skiing, snowboarding, hiking, and cold-weather activities with reliable performance.

Workwear & Industrial Distributors

Create heated solutions for construction, warehousing, and outdoor work environments requiring safety and durability.

E-commerce Sellers

Build private-label heated products with custom branding, packaging, and performance specifications.

Product Upgrade Teams

Improve existing heated products with better reliability, safety features, and manufacturing efficiency.

What We Design

We support the full heated system stack—from heat generation to power control—so you can develop a product that performs consistently and is easier to manufacture at scale.

System & Electronics

- Heating system architecture (heat zones, modes, runtime targets)

- Temperature control behavior (levels, safety limits, feedback options)

- Controller solutions (button, remote control, app-enabled options)

- Battery & charging matching (capacity planning, connectors, chargers)

Integration & Materials

- Heating element selection (film, carbon fiber, wire) based on flexibility and heat distribution

- Product integration (placement, routing, comfort, durability)

- Sizing and fit considerations for heated apparel and accessories

- Manufacturing readiness (BOM alignment and critical checkpoints)

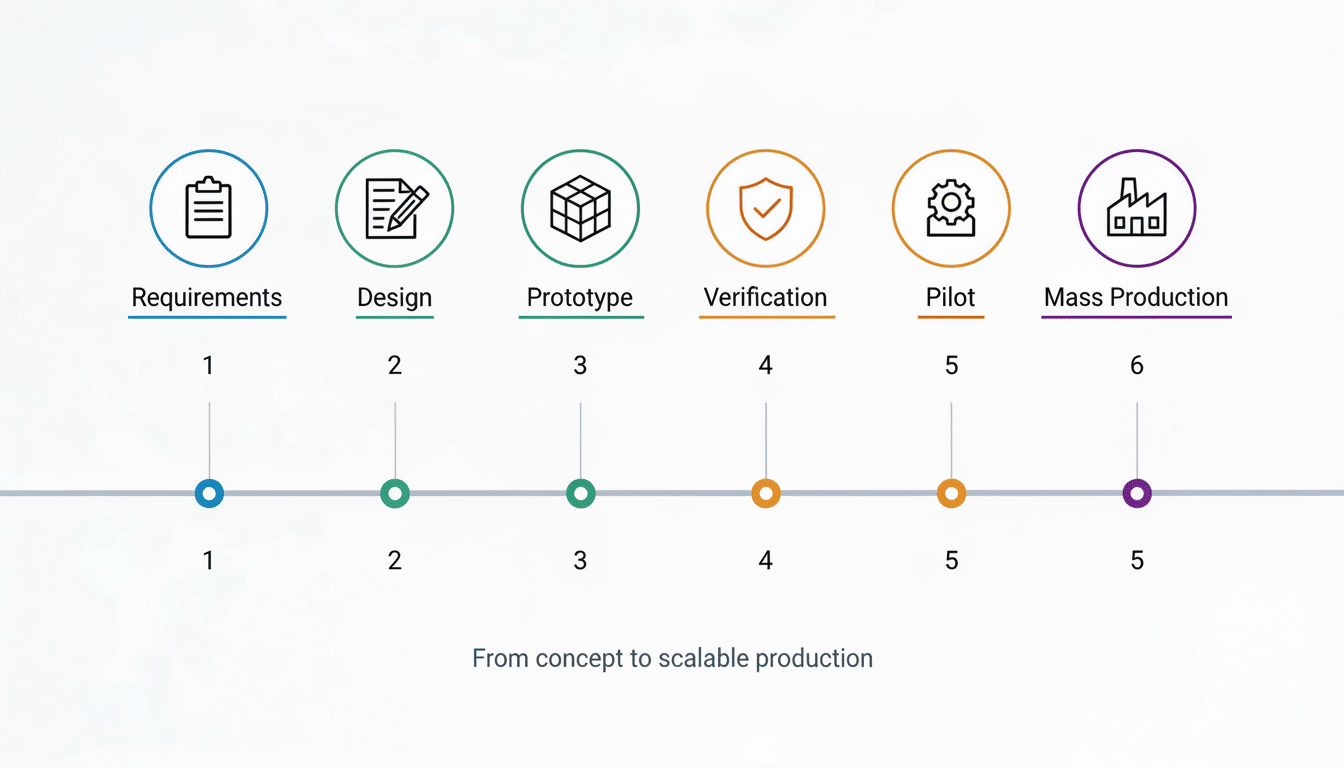

Our Development Process

A structured process helps reduce redesign cycles and improves production stability.

You’ll always know what stage we are in, what decisions are pending, and what we need from you to move forward.

What You Get (Typical Deliverables )

To keep projects predictable, we document the key decisions that affect warmth, runtime, safety, and manufacturability.

- System specification: heat zones, temperature levels, runtime assumptions

- Control behavior definition: modes, indicators, protection logic

- Prototype samples and iteration change log

- Production-ready BOM alignment and QC checkpoints

- Packaging and labeling inputs for your target market

Proof of Engineering & Integration

We design with manufacturing in mind—routing, comfort, durability, and serviceability—so the product performs not only in samples but also in mass production.

Verification Mindset: Reliability Before Scale

Heated products combine electronics, batteries, and textiles—so we focus on verification early to reduce field issues later.

We implement quality control from incoming inspection to final inspection and aging checks, with attention to safety-related behaviors such as over-temperature protection.

FAQs

Can you develop a fully custom heated product (ODM )?

Yes. Share your target users, use scenario, reference styles, and heating expectations, and we’ll propose a practical development route and prototype plan.

Do you support remote control or app control?

We can support button, remote, or app-enabled solutions depending on product category, complexity, and target price point.

Can you support small-MOQ customization?

For many projects, yes. Final MOQ depends on materials, electronics, and any tooling requirements.

Which product categories do you support?

Common categories include heated insoles, socks, gloves, vests, jackets, base layers, pants/leggings, and heating pads.

Request a Design Review

Tell us what you’re building and where you plan to sell it. Our team will reply with a clear next-step plan for sampling and development.