Introduction — Why Heated Apparel Requires More Certifications Than Normal Clothing

Heated clothes are not a piece of clothing but an electronical screened wrapping of the textile and that means that it is subject to closer regulatory attention than your regular winter coat. The assembly of batteries, heating devices, and wires presents such risks as electric shocks, chemical infiltration of materials or battery damage during transportation. Since my experience as a compliance engineer, with more than ten years of experience, and working with organizations such as ours like Dr. Warm, I have observed how not adhering to certifications may stop shipments or result in expensive recalls. An example is, a hot jacket that has not been battery tested correctly could be detected at the customs or a jacket made of non-complicated material may not pass the entry to the EU market. These standards are not hurdles in a bureaucracy, they are protection against products that in the real world work safely, such as wet gloves used by skiers in the Alps, or the vest used by a worker in a freezing warehouse. We are interested in these at Dr. Warm, where we focus on these since the design stage, to avoid causing surprises, based on our experience in Dongguan to attain the requirements of the world. Learning about them will guide the brands and manufacturers towards what they require to be safe, reliable, and be able to operate in the market legally.

Certification Category #1 — Electrical & Electronic Safety (CE / FCC)

Electrical certifications are aimed at making sure that the electronics in the heated apparel does not cause shocks or conflicts with other equipment, as the system will be low volt (low voltage).

CE Certification (Europe)

CE marking is an indication of compliance with EU regulations, mainly the Low voltage Directive (LVD) to ensure safety at lower DC voltages under 75V and the Electromagnetic Compatibility (EMC) to ensure non-interference. In the case of heated clothing, this implies that circuits of the heating are tested to check their insulation quality and that there are no excessive emissions of control modules. EN standards, such as EN 60335 on household appliances, are frequently used, including such things as mechanical strength and abnormal operation.

The documents required are a Declaration of Conformity (DoC), technical file which contains design drawings and test reports of approved laboratories. At Dr. Warm, we have used EMC tests on glove controllers to ensure these items do not interfere with the radios nearby which were a common problem with inadequately shielded wiring.

FCC Certification (USA)

FCC Part 15 deals with inadvertent radiators, such as the microchips in temperature controls, to restrict the electromagnetic interference. In the case of heated clothing, it would mean the measurement of emissions of PCBs and compliance with thresholds of Class B of consumer products.

Why should non-wireless heated jackets even require FCC? The heating levels switching may produce noise. Our vests have been experimented in FCC approved sites with shielding varied to pass which is a prerequisite to entering the US without fines.

Why Heated Apparel Must Pass Electrical Safety Tests

These tests identify hazards such as overheating due to poor installation of wiring or short in wet environments. As an example, LVD tests showed that the insulation failed during flex in a glove project therefore the design changes. In their absence, it is true that users would experience mild shocks or failure of products, which would destroy the confidence. Such certs provide authority to ensure compliance, but experience tells that they are essential in the real world, such as wet clothing of a hunter in the field.

Certification Category #2 — Chemical & Material Safety (RoHS / Reach)

The chemical certification concentrates on the hazardous materials used, which is important in the heated apparel where the glues, coating, and other elements are in direct contact with skin.

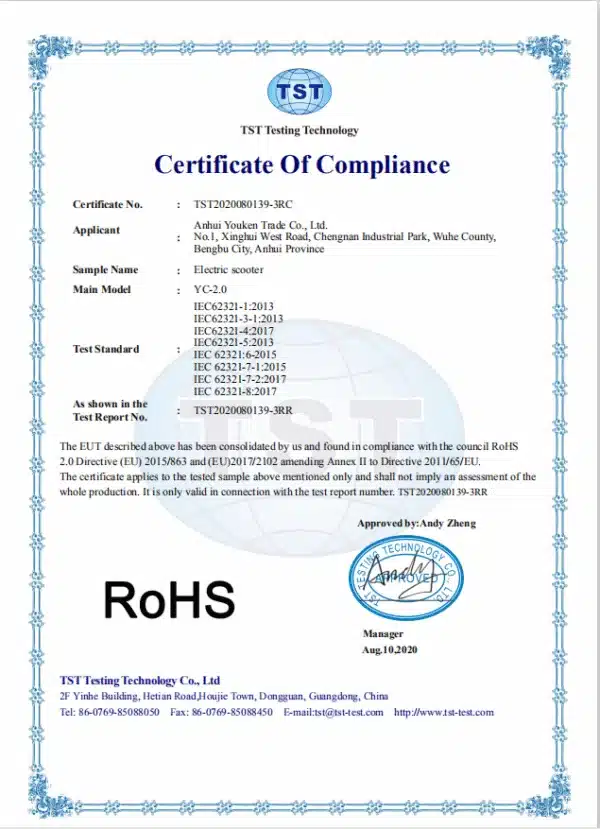

RoHS Compliance

RoHS limits the occurrence of heavy metals such as lead and cadmium in electronics, as well as flame retardants in cloths. In the case of heated garments, this covers solder in PCBs, dyes used in linings and coatings used on heating films, – there are very strict limits, such as 0.1% on most substances.

Testing includes XRF tests or laboratory tests; otherwise in the EU the product can be outlawed. To comply with RoHS we have changed the jacket controls solder to lead-free, which does not present any problems during export audits.

REACH (EU)

REACH controls the chemicals in the supply chain, making substances such as phthalates in waterproof membranes or adhesives to be registered. In the case of heated clothing, it will involve screening foams of insulation and cloths treatment of SVHCs (substances of very high concern).

Why the focus? Long-term skin exposure in gloves or socks increases the risks of exposure. Our Vest linings have been tested using REACH and no restricted chemicals leach during use.

Why It Matters for Heated Clothing

Conductive inks that may contain restricted compounds may be used as heating elements, as well as glues to laminate them may contain VOCs. Lack of compliance results in health claims or market ban. RoHS testing in a socket line found cadmium in a dye, and was reformulated, which experience has shown, protects brands over the long run.

Certification Category #3 — Battery Safety (UN38.3 / UL / MSDS)

The most dangerous aspect is batteries, which drive heat, but can cause problems when handled inappropriately, and therefore special certs are required.

UN38.3 (Mandatory for Global Shipping)

UN38.3 tests Lithium batteries in transport safety: Altitude (low pressure), thermal ( -40degC to 75degC), vibration (shaking), shock (drops) or impact/crush, overcharge, and forced discharge.

In the case of heated garments, this will help the packs of gloves or jackets to withstand air transport without leaking. We have tested them on 7.4 V cells with vest batteries and have not found them to produce any fires when crushed.

UL Certification (Optional but High Trust)

UL 2054 is an electrical and fire safety test of battery packs including tests of abuse such as nail penetration. Although it is optional, it is gold in US markets encompassing enclosure strength and over-current protection.

UL-tested jacket batteries in our factory were a plus particularly in workwear where durability is of importance.

MSDS + Battery Specifications

Information about material safety Data Sheets (MSDS), which is necessary for the customs. It has specifications such as voltage, capacity and chemistry.

Why crucial? They are the direction of safe using and disposing. In the case of heated socks, MSDS facilitated a customer working around the airline restrictions on battery carry-on.

Why Battery Compliance Is Non-Negotiable

Bad batteries may overheat or even blow up–UN38.3 helps them not to do this during transit, UL when in use. Swelling cells in cold storage happened due to a glove project that was not properly tested, and such a risk could be prevented with these certs.

Certification Category #4 — Water & Weather Resistance (IPX Rating)

The protection against water is classified by IPX rating which is important in the heated clothing subjected to snow or sweat.

IPX4 / IPX5 / IPX6

The IPX4 is protected against splashes in every direction, and may be used in raincoats during light rain. IPX5 can be used to treat low-pressure jets, such as glove hose spray. IPX6 is powerful jet resistant, and can be used in heavy snow in socks.

During ingress testing, water is exposed to the power supply and checked. In the case of heated jackets, IPX5 is used to make sure that the controls remain dry when it is storming.

Why Heated Apparel Must Prove Waterproofing

Water and electricity = shorts or corrosion. Poor sealing in gloves of skiers resulted in powder-IPX rating failures to avoid hazards.

Certification Category #5 — Fabric Safety & Apparel Regulations

Textiles should be safe against skin-contact and fire.

Fire Resistance Standards

In some markets such as the US, the quality of workwear heat-insulated vests must be required to comply with ASTM D6413 flame resistance so that the materials self-extinguish.

In testing, samples are subjected to flames; in the case of jackets, this is important in the industrial application to prevent ignition by sparks.

Fabric Safety (OEKO-TEX Optional)

OEKO-TEX Standard 100 also has certification of non-toxic textiles, where harmful dyes or finishes in the textile linings are tested.

Elective, yet establishes confidence–in the case of heated socks to be worn over a long period of time, it promises that there are no skin irritants.

How Certification Requirements Differ by Market

Specifications are not universal, which influences the design and the cost.

Europe (CE + RoHS + REACH)

Electronics (CE), material (RoHS) and chemical (REACH) are stringent. Control of heated gloves requires complete EMC testing, and SVHC statements of fabrics. Practice indicates that this increases 4-6 weeks per timelines but facilitates entry.

USA (FCC + UL optional)

FCC on the emissions is compulsory; UL enhances reliability on batteries. In the case of heated jackets, the FCC Part 15 is not subject to interference, and the pack safety in the UL 2054 voluntary standard is not mandated, although most brands are willing to pay the liability insurance.

Canada

Just like FCC concerning ICES standards of interference; RoHS-like of materials. Battery UN38.3 is important to import; a socket line that I was working on required IC certification on wireless remotes.

Japan / Korea

PSE (Japan) and KC (Korea) on electrical safety, including battery and wiring. PSE Mark is needed in heated vests and leakage current-local lab tests are frequently required.

Australia

RCM is a mix of EMC and safety, as is the case with CE. In the case of heated apparel, this involves AS/NZS standards; UN38.3 standard specifies compliance of air shipping of batteries.

What Documents Factories Must Provide (Compliance Checklist)

The following should be supplied by the factories to: CE DoC: risk assessment, FCC test reports in accredited labs, RoHS analysis certificates, UN38.3 summaries, MSDS of batteries and IPX reports with photos. In the case of a glove project, PCB schematics was required to perform internal EMC checks and QC documentation such as heat maps. These generate an audit in a technical file, which is traceable.

Common Certification Mistakes Buyers Make

Assuming CE/FCC logos = real compliance

There are counterfeit labels everywhere- never trust the work of laboratories such as TUV. Forged CE jacket line was turned back at port.

Not verifying UN38.3 until shipping

Without, it cannot be air freighted with batteries. Test early.

Testing only the garment but not the battery

Separate UN38.3 compliance of whole product is needed on batteries otherwise.

Using uncertified fabric or insulation material

RoHS/REACH is applicable in this case; uncertified dyes made a sock batch to fail a chemical test.

Trusting trading companies without test reports

Traders usually are in lack of docs–demand of the real factory.

How to Ensure Your Heated Apparel Truly Meets Compliance Standards

Verify Reports With Test Labs

Contact laboratories such as SGS to verify authenticity – this is how I have verified fakes on glove certs.

Confirm Factory’s In-House Testing Capabilities

Search thermal chambers or EMC rooms; those that are dependable invest into this to speed up iterations.

Use Pre-Certified Components

Existing UN38.3 battery makes the process faster-source of vetted suppliers.

Perform Sample-Level Testing

Check prototypes on their own to check factory claims prior to production.

Final Recommendation — The Certification Roadmap for Heated Apparel

Begin with CE + RoHS + REACH in Europe, FCC + optional UL in the USA and always UN38.3 in the case of batteries. Include IPX in wet-use products to make them waterproof. Make decisions according to markets- Europe inspections full, USA electronics specializations. Adequately adhering is not only a way of escaping the law, but it develops consumer confidence by providing safe and reliable equipment. Find established factories to carry you through this and your hot garments will be successful anywhere in the world.