Branded Bluetooth App Control for Heated Apparel (OEM/ODM)

Launch app-enabled heated insoles, socks, gloves, jackets, or vests with a complete solution—BLE controller, firmware, battery options, and a branded iOS/Android app UI—built for stable connections, safe heating, and scalable production.

Factory-direct OEM/ODM • ISO-aligned QC process • CE/RoHS/FCC-ready configurations

Built for brands that need app-enabled heated gear

This solution is designed for brands, distributors, and e-commerce sellers who want to upgrade from button control to app-controlled heating—without managing separate suppliers for electronics, firmware, and manufacturing.

- You already sell heated apparel and want a premium, app-controlled product line.

- You’re launching a new heated insole/sock/glove/jacket collection and need an end-to-end OEM/ODM partner.

- You want a branded app experience (logo, colors, languages) to match your product positioning.

What we deliver in an app-control project

You receive a clear scope that connects software to hardware, so the final product works reliably at scale.

Branded App UI/UX

Logo, theme colors, onboarding screens, and multilingual UI options.

BLE Device Control

Pairing, heat level switching, timers, and left/right device management.

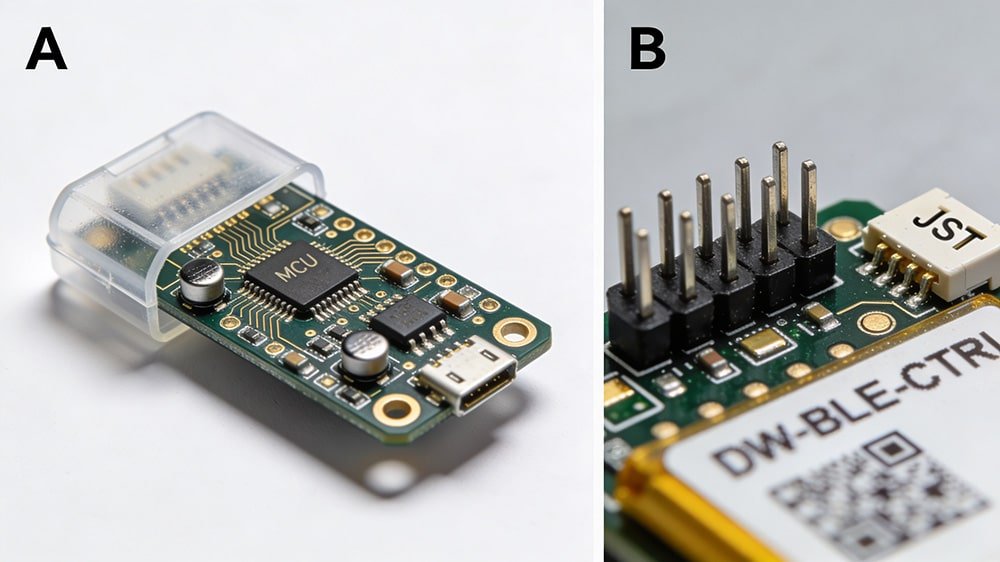

Controller + Firmware

Communication protocol, stability tuning, and error handling.

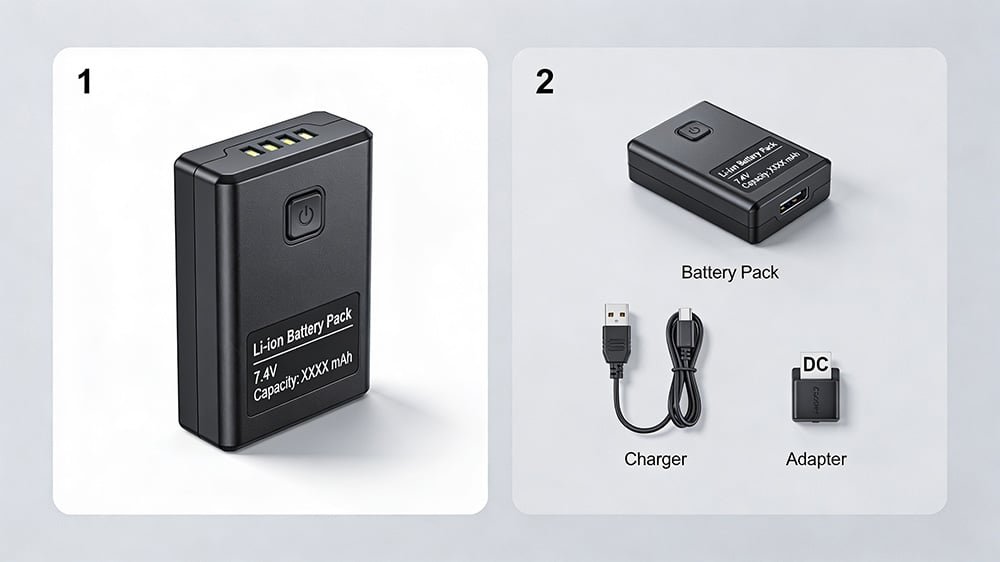

Battery & Safety Logic

Display and logic support, with feasibility confirmed before sampling.

Manufacturing Docs

BOM, specifications, test checklist, and packaging requirements.

Supported heated product categories

Heated Insoles (App Control)

Ideal for skiing, hunting, and outdoor work where users want quick temperature changes and battery visibility. Typical app functions include heat levels, timer/auto-off, and dual-insole pairing.

Heated Socks (Bluetooth App Control)

Suitable for sports and cold-weather daily wear, especially when customers want a cleaner "no-button" look. We can align heating performance with sock structure, materials, and target runtime.

Heated Gloves (App-Controlled Heating)

Great for motorcycle, winter sports, and tactical use where usability matters with gloves on. App control can simplify heat adjustments and support paired glove management (left/right).

Heated Jackets & Vests (App Enabled)

Common for outdoor brands and workwear lines needing comfort plus safe temperature control. We can support different heating-zone layouts depending on garment design and controller channels.

App features buyers ask for most

We build features that make sense for heated gear users and are realistic for mass production.

- Heat levels & modes: e.g., Low/Medium/High; custom level mapping possible based on heating system design.

- Timers and auto shut-off: designed for safer use and battery management.

- Battery indicator: percentage/level display requires compatible battery/controller data.

- Multi-device management: pairing, naming devices, managing pairs for insoles/gloves.

- Brand customization: app icon, splash screen, UI theme, text languages.

- Support-ready UX: simple troubleshooting prompts for pairing and connection issues.

One integrated system, not scattered components

To make app-controlled heated apparel stable, the app must match the controller firmware and heating design.

What’s included in the system

- Mobile app (iOS/Android UI and control logic).

- BLE heating controller (hardware + firmware).

- Battery options (capacity selection based on product type and runtime target).

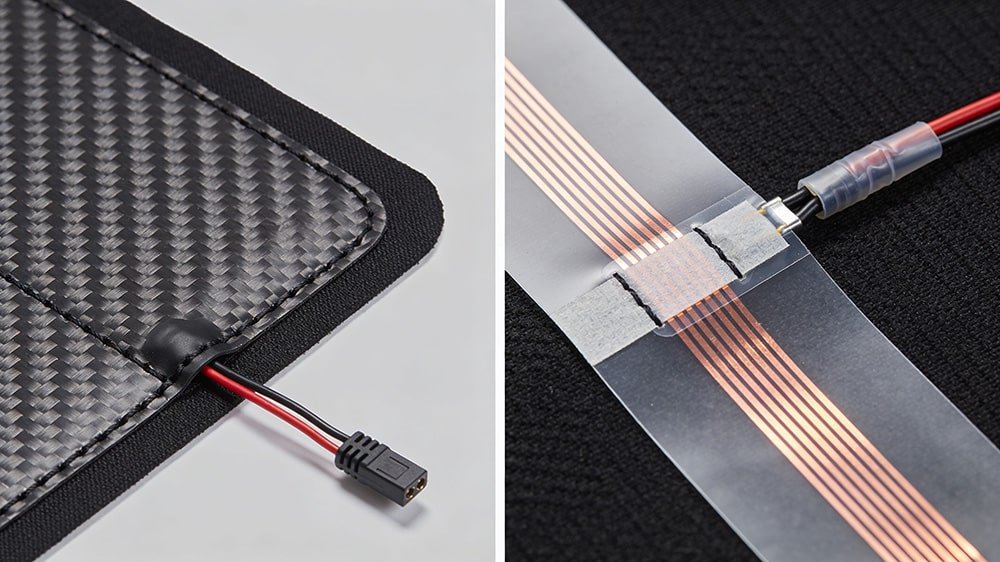

- Heating elements (film / carbon fiber / wire options depending on product category).

- Chargers and accessories (as required by the final package).

From requirement to mass production

Our process is built to reduce risk before you scale.

- Requirement intake: product category, target market, app functions, target price, timeline.

- Proposal & system selection: controller + battery + heating element recommendation.

- App UI/UX draft: branding, screens, user flow + function confirmation.

- Prototype development: app + controller firmware integration and sample build.

- Stability & safety verification: pairing reliability, heating behavior, protection logic checks.

- Pilot run and packaging confirmation: labels, manuals, accessories.

- Mass production + QC plan execution: incoming inspection, in-process checks, final inspection.

Engineering validation and quality testing

For app-enabled heated products, connection stability and heating safety must be verified—not assumed. Our testing workflow helps reduce returns and protects your brand experience.

Information we request to quote accurately

Share these details and we can scope the project faster.

- Product type (insoles/socks/gloves/jacket/vest) and heating zones.

- Target market (US/EU/UK/etc.) and required compliance approach.

- Desired app functions (heat levels, timers, battery display, device pairing logic).

- Target runtime and preferred battery size/weight constraints.

- Branding assets (logo, brand colors, app name) and languages.

- Forecast and target MOQ for the first order.

Choose the right app model for your brand

Option A: White-label branded app (recommended for brands)

We build a branded app experience aligned with your product line (UI theme, app name, and customer-facing flow). This option fits brands that want stronger differentiation in app stores and marketing.

Option B: Shared framework + brand UI theme (faster launch)

For time-sensitive projects, we can use a validated app framework and customize the branding layer and product configuration. This option is often faster while still giving a branded look and consistent device control.

Quality control and compliance alignment

App-enabled products still require the same manufacturing discipline as traditional heated apparel—plus extra attention to electronics stability.

- ISO-aligned quality management approach across incoming materials, electronics testing, and final inspection.

- Safety checks may include heating endurance, over-temperature protection behavior, and battery safety verification based on the selected system configuration.

- Compliance targets can include CE/RoHS/FCC/UKCA/UL testing pathways depending on your market plan.

Frequently asked questions

Yes—projects can include a branded UI/UX and the control functions required for your heated apparel, based on the final controller and firmware capability.

It depends on whether the battery/BMS and controller provide usable data for accurate reporting. We confirm feasibility during the proposal stage.

Yes, when the controller solution supports paired device management and the product design requires it.

MOQ depends on the product category, materials, and whether you need custom electronics or a standard controller solution. Share your target and we’ll recommend the best launch approach.

Yes—heat levels and output can be tuned through heating element layout, insulation/material choices, controller settings, and battery capacity selection.

This can be done by your brand (most common) or defined as part of the project scope. We align on responsibilities, timelines, and required assets early to avoid launch delays.

Ready to build your app-controlled heated product line?

Send us your product category, target market, and required app functions. Our team will respond with a recommended system configuration and a project timeline.