Custom Heated Insoles Manufacturer & OEM/ODM Factory

Tailor-made heated insoles with advanced heating systems, reliable battery safety, and full OEM & ODM support for global brands.

Advanced Heating Technology

Even heat distribution with stable temperature control

Safe & Certified Batteries

Rechargeable lithium systems with multi-layer protection

OEM & ODM Customization

Design, heating zones, control systems, and branding

Fast Sampling & Scalable Production

Prototypes in 7–10 days, mass production ready

Global Compliance

CE, FCC, RoHS, UKCA & ISO-aligned quality system

Why Choose Custom Heated Insoles?

Custom heated insoles are designed around real usage scenarios rather than generic templates. By customizing heating zones, power output, and materials, brands can achieve more even warmth, better comfort, and improved battery efficiency—whether for skiing, outdoor work, or daily winter use. This results in longer runtime, more stable temperature control, and a noticeably better user experience.

Compared to off-the-shelf products, custom solutions also offer higher safety and stronger brand differentiation. Optimized battery systems, multi-layer protection, and tailored control options help ensure reliable performance in cold environments, while flexible design and branding allow products to better match market positioning and customer expectations.

Our Custom Heated Insoles Solutions

How We Manufacture Custom Heated Insoles

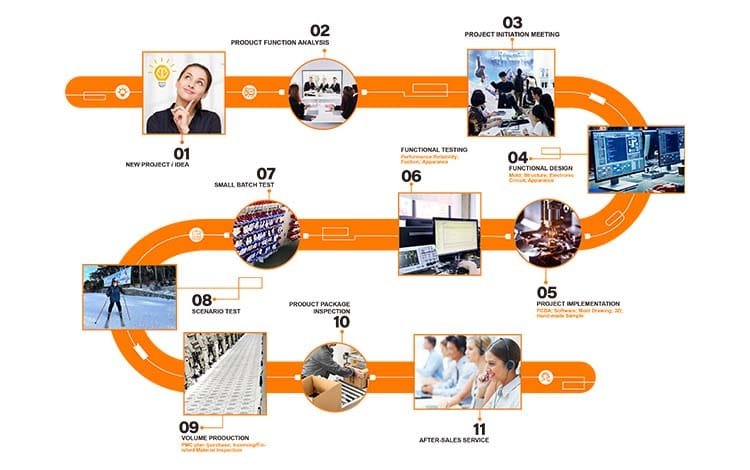

From concept design to mass production, we provide a complete OEM & ODM manufacturing process for heated insoles.

Heated Insole Concept & Requirements

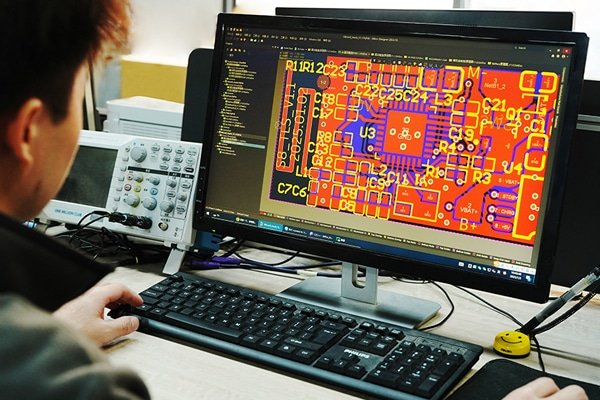

Heating System & Circuit Design

Insole Structure & Material Selection

Battery, Controller & APP Options

Prototype Development & Sample Testing

Client Sample Confirmation

OEM Bulk Manufacturing

Custom Packaging & Global Shipping

Customization Options for OEM Heated Insoles

Custom Heated Insoles Made Easy for Your Brand

Custom Heating Zones & Power Levels

Forefoot, heel, or full-sole heating with adjustable temperature settings.Battery & Control Solutions

Built-in or detachable batteries with button control, remote control, or Bluetooth APP.Insole Materials & Structure

Custom thickness, cushioning layers, and materials for comfort and durability.Branding & Private Label

Logo printing, custom packaging, and private label solutions for your brand.OEM & ODM Engineering Support

From concept design and prototyping to mass production and quality control.

Trusted Heated Insoles Manufacturer – Why Choose Dr. Warm

About Dr. Warm

Dr. Warm is a professional manufacturer specializing in electric heated wearables, with a strong focus on heated insoles, socks, gloves, and jackets. Based in Dongguan, China, we combine in-house R&D, electronic heating system development, and standardized manufacturing to deliver reliable OEM & ODM solutions for global brands.

From heating system design and battery integration to mass production and quality control, our factory operates under ISO-aligned processes and international compliance standards. With years of experience serving outdoor, workwear, and winter sports markets, we help partners bring safe, high-performance heated products to market efficiently.

From product concept and heating system design to tooling, testing, and mass production, we provide complete OEM & ODM services tailored to your market needs.

Our engineering team develops heating elements, temperature control systems, and battery protection solutions to ensure stable performance and user safety.

All products are designed to meet international standards including CE, FCC, RoHS, UKCA, and UL testing, with strict quality control at every production stage.

We support flexible minimum order quantities and fast prototyping, helping brands test markets and launch new products efficiently.

From initial consultation to after-sales support, our experienced team ensures smooth communication and reliable project execution.

Custom Heated Insoles FAQs

Our standard MOQ for OEM custom heated insoles is 500 pairs per style. For ODM projects or existing designs, we may support lower quantities depending on the configuration and customization level.

Heating time typically ranges from 4 to 10 hours, depending on battery capacity, heating power, and temperature settings. Custom battery solutions can be optimized based on your target usage time and market requirements.

Yes. We offer multiple size options as well as trim-to-fit designs. Insole thickness, shape, and structure can also be customized to match different footwear types and user preferences.

We provide both built-in and detachable rechargeable lithium battery systems. Battery capacity, output power, and protection features can be customized to balance heating performance, runtime, and safety.

Yes. Custom heated insoles can be equipped with manual button control, remote control, or Bluetooth APP-based control, allowing users to adjust temperature levels conveniently.

All heated insoles are designed with multi-layer safety protection, including over-temperature protection, short-circuit prevention, and battery safety management. Products undergo heating endurance and functional aging tests to ensure safe operation in cold environments.

Applications of Custom Heated Insoles

Cycling & Motorcycling

Helps maintain foot warmth during cold-weather riding without restricting movement or comfort.

Skiing & Snow Sports

Provides consistent foot warmth during skiing, snowboarding, and alpine activities, even in extreme cold conditions.

Hunting & Fishing

Keeps feet warm and comfortable during long hours of low-movement outdoor activities in winter conditions.

Outdoor Work & Construction

Ideal for workers in cold environments such as construction sites, logistics yards, and cold storage facilities.

Daily Winter Wear

Designed for everyday use, offering lightweight warmth for commuting, walking, and daily outdoor activities.