Introduction — Why Battery Capacity Determines Heated Clothing Performance

The battery in a thermal clothing project is not merely a source of power the battery is the foundation upon which you determine how long the appliance will remain hot, how consistently the temperature will stay, and even how comfortable and safe the final production will be. Being a battery engineer, and having consulted OEMs on heated clothing systems with more than 15 years of experience, I have witnessed inappropriate capacity matching capacities to unhappy users with limited run times or oversized appearance that hinders movement. Capacity is connected with such factors as runtime, temperature stability, weight, and battery safety of heated clothing. Small, and the heat is lost in the middle of the shift; too big, and you will be adding unnecessary bulk and expense. This is particularly important to the battery capacity calculations of heated clothing in the design of items such as jackets or gloves where an end user wants to be sure that the clothing will perform well in the freezing conditions. Knowledge of battery runtime will make sure that your designs match the field, whether it is in an outdoor sport or in work-wear.

The Core Principle — Battery Capacity = Power Consumption × Runtime

First and foremost, the key principle that must be considered when working on any kind of heated clothing project is the following: Battery Capacity (Wh) = Heating Power(W) x runtime (hours). There is no need to have your head turned about calculating the size. The formula takes you straight to it. My experience with hundreds of OEM builds of similar nature has shown that it is much better to view Wh (watt-hours) than to view mAh since mAh is a measure of charge but does not tell you how much energy you can use unless you have voltage applied. mAh vs Wh battery heated debate Veterans of the industry have long been telling beginners to go squarely into Wh (watt-hours) rather than to go squarely into mAh because mAh is a measure of charge but it does not tell you about the amount of energy you can use unless you have voltage applied. Use Wh to be precise; it is the measure that will be able to tell exactly how long your heated clothing power consumption can keep you warm. We will separate this further, but begin with this: Find out the wattage of your system, multiply with hours you desire, and herein you have the base of your capacity requirement.

Understanding the Key Battery Concepts

You must have a good understanding of the fundamentals to compute the battery capacity to warm clothing or you will be inaccurate in the sizing.

What Is Wattage (W)?

Wattage (W) is the amount of power consumption of your heating system, simply the speed at which your temperature generator uses power to heat. In heat wear, it is provided by such components as carbon fiber or graphene films. What is increased in W is increased heat and decreased drain– consider 10-15W jacket vs.3-5W socks. Calculation of wattage of heated clothing begins with accurate calculation of the wattage of this based on your elements.

What Is Voltage (V)?

The system is driven by voltages and typically includes 5V, 7.4 V or 12 V voltage options which have implications on the heat levels as well as compatibility. The 5V is the kind of voltage that is used in lightweight consumer devices whereas 12V is used in industrial configurations to provide deeper heat.

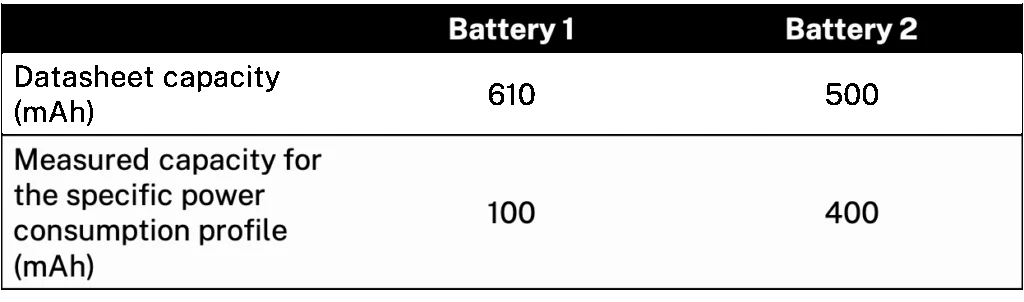

What Is mAh? Should You Trust It?

Milliamp-hours (mAh) is an indicator of the charge capacity, but alone it is misleading. Five thousand amperes of a battery running at 5 V contains less energy than 5000 amperes of a battery running at 7.4 V. When using in hot apparel battery guide conditions, it must always be paired with voltage otherwise you are operating in the dark on the run time.

Why Is the Only Accurate Unit

Wh measures total energy, and thus is necessary. It is simply converted as Wh = (mAh /1000) x Voltage. This equation determines the battery size, which should be used to heat your jacket or gloves, and not traps of mAh specifications.

Step-by-Step Method — How to Calculate Battery Capacity

This is my prototyped process that I have optimized as an OEM–do it so that you do not need to discover it through trial and error.

Step 1 — Identify Heating System Wattage

Measuring heating element power consumption. Average circumference: Jackets, Gloves, Socks, Vests: 10-15W, 5-7W, 3-5W. Test prototypes or supplier information with a multimeter.

Step 2 — Decide Required Runtime

Consider user requirements- 2 hours of short day, 4-6 hours of daily usage, 8 or more hours of full time work. Cold external conditions enhance draw hence add 20 percent buffer.

Step 3 — Use Runtime Formula

Plug in: Battery (Wh) Desired Runtime x Wattage of Heating. This provides your energy objective.

Step 4 — Convert Wh → mAh for Final Battery Spec

In the case of specification of lithium packs: mAh = (Wh/Voltage)1000. This will be done to make sure that there is compatibility in custom heated apparel battery sizing.

Examples — Calculate Battery Size for Real Heated Apparel

We can use this on real world situations, using real numbers of projects I have worked on as an engineer.

Example 1 — Heated Jacket (12W, 6 hours)

To determine the size of battery that should be used to power a heated jacket with a power of 12W and a run time of 6 hours: Wh = 12W x 6h = 72Wh. At 7.4 V (typical jacket) mAh = (72/7.4)x 1000 [?] 9730mAh. Safety Round off to 10,000mAh – ideal with a mid-range outdoors model.

Example 2 — Heated Gloves (6W, 4 hours)

Some battery-pack products in use have per-hand packs. In case of 6W in total (3W per glove) and 4 hours: Wh = 6W x 4h = 24Wh. At 7.4V: mAh = (24 / 7.4) x 1000 [?] 3243mAh. 800mAh (3500) per pair, divided into two 1750mAh units – I have used this arrangement with great success in skiing gloves.

Example 3 — Heated Socks (4W, 8 hours)

In the case of 4W (2W/ socket) and 8 hours of use: Wh = 4W/8h = 32Wh. At 5V for lightweight: mAh = (32 / 5) x 1000 = 6400mAh. Choose the 7000mAh to consider the cold drain-perfect fit to the warehouse workers.

Example 4 — Heated Vest (10W, 5 hours)

optimum battery size at 10W and 5h of heated vest Wh = 10W x 5h = 50Wh. At 12V for robust heat: mAh = (50 / 12) x 1000 [?] 4167mAh. Order 5000mAh- this combination is useful to run utility vests.

Voltage Differences — 5V vs 7.4V vs 12V Battery Systems

Capacity choice and performance are determined by voltage choice.

5V System

The 5 V has low heat to be worn casually, such as base layers. Advantages: USB compatible, small, disadvantages: low power, increased mAh to reach same Wh.

7.4V System

The everyday, all-purpose, heated clothing, all size/heat. It is fitting well in 7-10W systems, such as jackets or gloves.

12V System

In high-demand such as motorcycle gear that needs a lot of power, 12V may be scorchingly warm but it takes more serious batteries–beefy in wearables.

Battery Selection for OEM Heated Apparel Projects

In OEM cases, there is a need to select battery OEM of heated apparel requires comprehensive planning.

Performance Requirements

Make trade off short-run levels (high W reduces run time) vs. scenarios of the user–target run time of 4-6 hours.

Fabric + Heating Element Compatibility

Make sure that the batteries fit into pockets in a non-bulky way; ensure that they are matched to elements to calculate the best lithium-ion battery to wearables.

Safety Requirements

Put a strong focus on UN38.3 / CE / FCC / RoHSs certifications which is necessary during transportation and compliance.

Cost Impact

The increase of Wh increases expenses 20-50% so maximize 2 market-budgets 5V, premium 7.4 V.

Common Mistakes When Choosing Battery Capacity

These are some of the traps that I have fallen into when reviewing clients.

Only looking at mAh, ignoring voltage

This causes under-size packs–invariably change to Wh.

Choosing a battery too small for high heat levels

Underrates the heating appliances power consumption resulting in premature fade-outs.

Overestimating runtime at low temperatures

Real conditions Decrease efficiency 20-30% in cold.

Ignoring battery protection circuits (BMS)

Risks do not get out of control or shorts, and that is a big safety red flag, without BMS.

Recommended Battery Sizes by Apparel Category

Depending on field-tested settings:

- Jackets: 10,000-15,000 mAh @ 7.4V

- Vests: 8,000-12,000 mAh @ 7.4V

- Gloves: 2,000-3,000 mAh per hand @ 7.4V

- Socks: 1,500-2,500 mAh

- Pants: 5,000-8,000 mAh

These guarantee balanced performance-customisation.

Conclusion — Battery Capacity Must Match Heating Power + User Needs

Reducing the batteries required to power up a piece of heated clothing is a simple matter of the basic equation of Wh = W x hours, which can then be converted to mAh; = (Wh / V) x 1000 with Wh being your guiding star above the deceptive mAh. Since it is step-by-step, calculating to voltages, such as 5 V or 7.4 V or 12 V, and with battery safety being a priority in heating clothing, this technique provides dependable runtimes. With OEM projects, factor in, fabric, and cost to success I have been able to take these principles and streamline lines lasting a full shift before complaints arise. Protest and test all the time; how many mAh required to heat gloves or jackets works out the correct numbers and customers remain warm and brands keep up with competition.