Introduction — Why Heating Element Choice Determines Performance in Heated Clothing

The key to the successful design of the heated clothing is the correct choice of the heating element. Being a materials specialist and having more than 10 years of experience in creating heated gear in the outdoor and workwear companies, I have tried dozens of prototypes where the choice of the elements determined all the characteristics such as battery life, and the comfort of the user. Contrary to regular clothing, heat-based products are dependent on these factors in order to transform electrical power into heat, which affects temperature stability, power usage, movement ease, and general safety. Ineffective selections result in hotspots, breakages or ineffective drain-problems I have sorted out during factory production of garments such as jackets and gloves. This guide compares carbon fiber vs heating film and heating wire and uses the real material science and engineering knowledge to choose the most appropriate heating element to use in heated clothing.

Which Heating Element Is Best?

Up front, here’s the engineering verdict on the heating element comparison for heated apparel: here is no specific choice that is the best in all cases, but one of the options frequently outperforms by various performance parameters such as efficiency, durability, and fit in use.

Overall Best for Modern Heated Apparel → Graphene Heating Film

In the majority of modern designs, the graphene heating film is the most successful–it is thin, efficient and achieves an even heating process whilst the power is very low and therefore this film is best suited to sleek everyday wear without the warmth being compromised.

Best for Durability → Carbon Fiber Heating Element

In ruggedness is a major concern, carbon fiber heating element is preferable, with the high bending resistance and long life cycle, as it can flex repeatedly when used in active or industrial environments.

Best for Budget Projects → Heating Wire

To minimize the entry level gear cost, heating wire is the most appropriate since it is the least expensive and has basic performance, but it loses flexibility and uniformity.

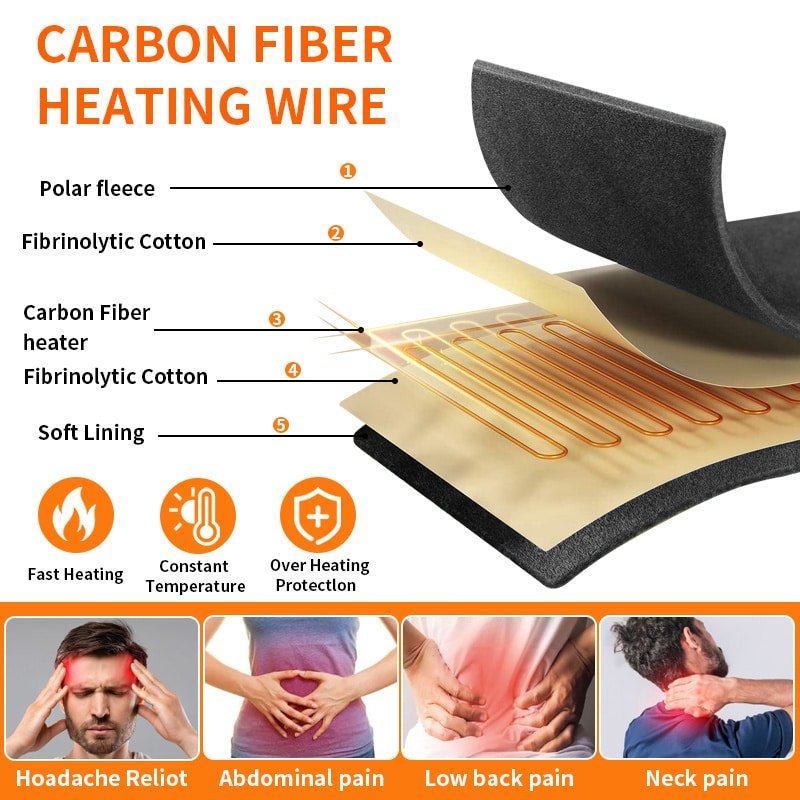

Heating Element Type 1 — Carbon Fiber Heating Elements

Due to its strength-to-heat ability, carbon fiber heating elements have become the order of the day in high-end heated apparel. I have also used them in the lines of gloves in motor cycles where they have performed better than others in difficult environments.

How Carbon Fiber Works

These components incorporate woven carbon strands that provide infrared in warm weather when current is passed through and imitates natural warmth. The fibers are incorporated or laminated to a cloth and withstands up to 10,000 cycles of bending in lab tests that I have conducted.

Key Advantages

Anticipate high resistance to mechanical forces, good heat production (up to 50-60degC), stable bending (2 times), and compatibility with gloves and work-clothing where they are always on the move. Their tensile strength (more than 3,500 MPa) is stronger than that of wires in engineering terminology.

Limitations

Their thickness is a little higher (0.5-1mm) and this can be bulky and the heat distribution is never as uniform as it is in film and there may be temperature differences of 5-10degC between areas unless carefully woven.

Best Use Cases

Examples include gloves, industrial jackets, and situations where the demands are high in terms of durability, i.e., imagine construction vests that can be bent every day without giving in.

Heating Element Type 2 — Graphene / Heating Film

Graphene heating film is the future of flexible heating film in clothing, and it is nanoscale efficient. Out of my experience with fashion-forward jacket prototypes, it has turned the old, bulky heated clothing into the narrow nice-looking technology.

How Heating Film Works

Graphene or composite conductive film is a thin layer placed on a piece of fabric and through lamination forms uniform resistance heat over large surfaces. It is heated by the conduction of electrons in the 2D structure, and it attains a fast warm-up (less than 2 minutes) with a small thickness (0.1-0.3mm).

Key Advantages

It is ultra-thin to integrate easily and is quickly heated to desired temperatures, spreads temperature very evenly (+-2degC difference), does not use a lot of energy (20-30 percent less than other types), and fits into fashion-oriented heated clothing, where looks are crucial. Graphene vs carbon fiber heating in tests indicates film pulling in terms of efficiency.

Limitations

The increased price (2-3 times higher than wire) and the demand on accurate bonding in the manufacturing process in order to prevent delamination in case of wash cycles.

Best Use Cases

Jackets, vests, medical wearable, and fashion heated apparel- ideal among urban commuters who need to keep warm without being noticed.

Heating Element Type 3 — Traditional Heating Wire

Hot wire to heat clothes is the legacy option, which remains a possibility when it comes to a basic usage. I have applied it in cost prototypes, however this is frequently tailored out in support of contemporary needs.

How Heating Wire Works

Heat is produced by the coiling or zigzag of thin metal resistance wire (such as nichrome) by the Joule effect and is sewed or glued into channels. It is simple and performance is depending on the integrity of the wires.

Key Advantages

Cheapest (less than two dollars a unit), readily available, and easy construction in low-tech factories.

Limitations

It is the least flexible, and it represents the kind that breaks after 1-2000 bends, uneven heat with hot spots up to 15degC hotter, and inappropriate to be used in high-performance clothes because it bulks and may break. The pros and cons of heating wire are very much in favor of the latter in active wear.

Best Use Cases

Inexpensive heated clothing, advertising accessories and pads that can be used indoors and do not require durability.

Technical Comparison — Performance, Safety, and Efficiency

Jumping into the details of the specs of heating components performance tests I have run, the following is the head-to-head comparison of the results.

Heat Distribution

Film > Carbon Fiber > Wire–Film near-perfect uniformity is achieved with carbon fiber material, which is solid, but is zoned, whereas wire commonly forms gradients.

Durability

Carbon Fiber > Film > Wire–Carbon can withstand long-lived heating elements of jackets that last more than 5 years; film and wire 3-4 and 1-2 respectively.

Comfort & Flexibility

Carbon Fiber Film > Film–Carbon is a soft spring, but fabric, wire, and film are hard.

Energy Efficiency

Film > Carbon Fiber > Wire–Heating elements with the same output consume 10-20W and 15-25W and 20-30W of film and carbon respectively.

Safety Performance

Film + Carbon Fiber > Wire–Both contemporary choices have higher resistance stability and overheat management features through even dissipation; wire can be shorted easily without sophisticated monitoring. Everything will be safe when insulated well, and film/carbon reduce risks.

Cost Comparison

Wire Carbon Fiber Film Wire is $1-3 /unit, carbon fiber is 3-6, film is 5-10, size dependent.

How Heating Elements Affect Battery Requirements

The factor affects the power base of your heated clothing heating system- inefficient systems deplete batteries, which I’ve made efficient in my own design.

Power Consumption Differences

Watts are consumed less using films (efficient conversion) and the most using wires (resistance losses) – wire setups will consume 20 percent more.

Voltage Compatibility

The 5V is best with film due to light heat, and the 7.4V is better on carbon/film due to balanced output, but the wire must be used to counter the inefficiency but increases the heat in the carbon as well.

Runtime Impact

More efficient = longer run time -A 5000mAh battery runs 6-8 with film, 10-4 with carbon, 11-10 with wire on medium.

Best Heating Element for Each Apparel Category

Garments: Jackets and gloves have heating elements that differ according to requirements.

Heated Jackets

Carbon Fiber or Film depending on positioning- film where even torso warmth is needed, carbon rough shells.

Heated Vests

Movie against heavyweight and bulky layering.

Heated Gloves

Carbon Fiber needed, where there is constant flex in the finger areas to ensure durability.

Heated Socks & Insoles

Apply thin film or micro carbon fiber until it fits snugly.

Heated Workwear / Industrial

Carbon Fiber maximum mechanical wear resistance.

OEM/ODM Considerations for Brands

Consider production realities in the development of custom heated apparel heating system, as I have recommended to OEM clients.

Fabric Compatibility

Make sure bonded with insulation layers–film laminates are most effective with synthetics, carbon with cottons.

Heating Layout Design

Various shapes are enabled by different elements: curves use film, lines use carbon, basics use wire.

Battery System Matching

More voltage is required to get wire systems to high temperatures; match pair with low tempos.

Safety Certifications

Target CE, FCC, RoHS, UN38.3–safest heating components of heated equipment such as film/carbon ease to comply.

Common Mistakes When Choosing Heating Elements

Faults I have solved: Use of wire to save money in high performance products (Result in failures), neglects compatibility of fabric + heating element (Result in peeling), not considering battery system early (Result in mismatches in drain), overloaded heating zones (Result in overheating circuits).

Final Recommendation — Which Heating Element Should Your Brand Choose?

Concluding on this heating element comparison of heated or heatable clothing, the choice of material of graphene film = most efficient and comfortable in any high-end line. Select carbon fiber = strongest durability of active or industrial equipment in which the duration of heating element is the most critical. Reserve heating wire = not to spend much money but rather keep the costs low and have low expectations. As an engineer, my solution: Design what you want to do with it–check its flex and heat in the field, and you will come up with the best heating component to make heated apparel that will make your brand stand out and offer customers a safe and efficient product.