Introduction — Why Component Selection Determines Heated Apparel Performance

Now is where the magic -or the mishaps- comes in the component choice in the heated apparel; this is where the battery power, the heating logic, get wrapped up in fabrics and insulation which enhance or degrade the entire system. My experience as a senior product engineer on the OEM lines of outdoor products has taught me that compatibility is everything: A high-voltage battery which cannot be used in low-rated wiring may short, and thick insulation on a poor heating coil smother the warmth. The battery is the source of energy base, the level of heat is determined by the user control and efficiency, the protective shell is made of fabrics, and the insulation is a way to keep the heat where it belongs without adding bulk. Got this chain under your dress and your clothes will give you the same performance- believe that ski jacket will keep 120degF without getting hot fast at medium temperature. However, forget the interplay and you will have prototypes which perform dismally when subjected to cold tests or your safety standards such as UL standards. In one hunting line project, there was inappropriate fabric selection, which, when it was wet, was absorbing, which led to the deterioration of the heating parts in the middle of the season. Certification such as CE is the source of authority, however, it is all about the skill to use these pieces to match your intended application, be it an active skiing or a passive warehouse job. Put your attention here and you will develop a safe, effective and market-ready gear.

Step 1 — Choosing the Right Battery System

The workhorse is the battery, whose logic, which is voltage, capacity, and design determines the boundaries of heat production and run time, thus being the initial choice in any project.

Battery Voltage Options

Power is determined by voltage: 5V USBs are small and cheaper, and can deliver power to all day in a mild urban (not extreme heat) outfit, between 100-110degF of base layer or vest, 130-140degF of serious cold, but cannot do much more than 4-6 hours on medium, or it runs out of power, so 12V high-power options.

In hot clothing battery selection, in gloves where fingers have to thaw quickly, the best is 7.4 V because anything below that and hands become numb on the highway, and anything higher and the battery becomes too big to wear;

Battery Capacity (mAh vs Wh Explained Simply)

Capacity measures energy, mAh is the number in any headline, but to have the real picture also consider Wh (watt-hours) having 2000mAh at 7.4V in the article provides approximately 14.8Wh or about 3-5 hours of medium heat in sox. Increase to 4000mAh (29.6Wh) and the jackets can be charged up to 6-8 hours, albeit with extra weight.

There is a logic in the selection of battery in heated clothing: In the case of insoles, 1000-2000mAh makes them slim; jackets require 3000-5000mAh in bigger areas. We chose 2500mAh in an OEM project of commuters to achieve 4-hour ranges without pocket sag, but cold test revealed that 20% of the energy was lost below the freeze point, so we made changes to insulate.

Battery Cell Grade & BMS Protection

A grade cells having high discharge rate will guarantee the consistency of the heat; A grade may be cost effective but may not last in cold. The Battery Management System (BMS) is not negotiable, it controls against overcharge, short-circuit, and deep discharge to avoid the fires or swelling.

BMS with UL certification will be trustworthy as experience has shown, in a vest line, this raised the limit to 140degF and prevented burns when used over a long time. In the case of gloves, there is space with which to work; thus, compact BMS does not add bulk to safety.

Battery Shape & Placement

Pouch shapes are used in jackets in balancing out the hems and cylindrical packs are used in glove cuffs to access it easily. Placement is important to usability–it is concealed in the lines in our fashions, but it is displayed in swaps in our work clothes.

In hot apparel logic batteries, in socks, micro-pouch in ankles is not painful; one of my hunting projects taught me that when positioned wrongly, our ankle chafed, and so I remodeled that part.

Decision Flow — Which Battery Should You Choose?

When you are going skiing with high activity, you would want Li-ion 7.4V 2000-3000mAh, this will provide power to warm-up, but not too much weight. To hunt in cold still 5V 3000mAh gives more focus on long run time than power. A commuter could choose 5V USB 2000mAh to be portable and 12V 4000mAh to be used in freezers because of the continuous heat. The certifications such as the UN38.3 (safe shipping and use) should always be considered.

Step 2 — Choosing the Heating Levels

The heating levels convert battery energy into the useful warmth type, and their rationality, distance, and managing choice have to be in line with the systems strength in the sense that they should not drain or cause any discomfort.

Temperature Range for Different Clothing Types

The core areas of jackets are aimed at 100-130, fingers have 110-140, toes 100-120, leg 95-115. The range is based on the loss of body heat, more extreme.

Glooves must have peaks in hot clothing parts since the fingers can get chilled quickly; a work glove project revealed the necessity of having a work coat having a high temperature of 130degF to work with the tools at -10degF.

High/Mid/Low Heating Logic

High (130-140degF) 20-30W fast but short, mid (110-120degF) 15W slow but long, low (100degF) 10W slow. Logic: Battery-high to battery-high 12 V needed to eliminate strain.

Based on development, mid is default since overkill high leads to sweat on the assumption that there is insulation.

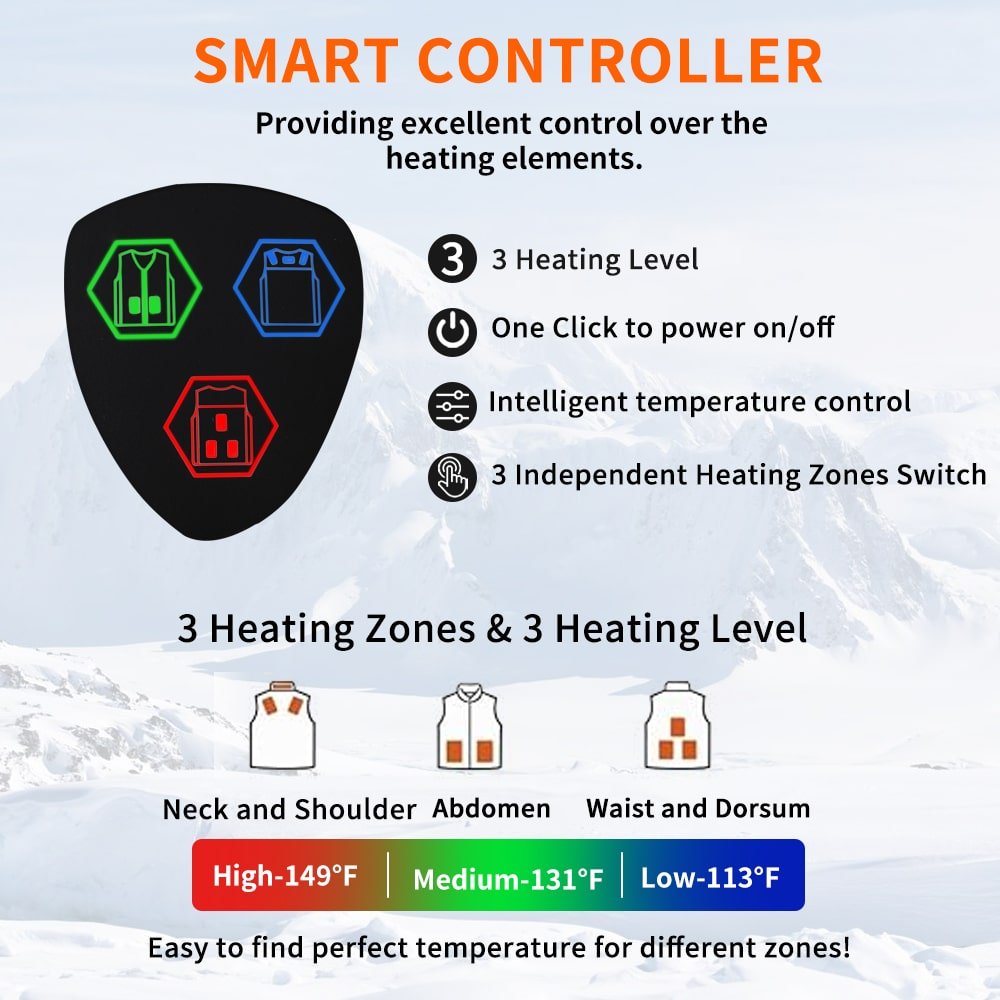

Control Method Selection

So 3-level switches are hardwired and can be used in basic applications; remotes can be used to add RF convenience in layered applications; apps can be used to add precision and sensors in Bluetooth applications; thermistors can be used as in auto regulation.

In the case of OEM, switches would fit into a budget, in a jacket line remotes improved the convenience of those people who needed to adjust on the fly.

Matching Heating Levels to Your Target Market

And skiers need high, and hunters mid, and workers stable mid, And city low mild. Market logic: Over-spec high consumes commuters.

Step 3 — Choosing Heating Elements (Core Technology)

The heat generators are called elements and their logic needs to be aligned with battery and fabrics to be efficient which consist of material, coverage and integration.

Carbon Fiber Heating

Advantage: Can bend in all directions, is very smooth and strong (100,000 bends), and disadvantage: More expensive. Adheres to curve lines quite well.

It did not bend over in skier-poles projects in gloves.

Graphene/Composite Heating Film

Advantages: Lightweight, efficient, fast; disadvantages Less durable. Suits flat zones like backs.

Worn in the vests to keep the core warm per a commuter line.

Traditional Heating Wire

Advantage: cheap, focal, disadvantage: rigid, breakable. For simple vests.

Shun in action wear–wire reasoning was unsuccessful in a work glove that flexed again and again.

Heating Coverage Strategy

Check high- losses: Gloves fully filled finger, jackets full-sleeve. Plan: Unlimited power–zero battery-saving.

His toe-only in OEM due to full-foot being overheated.

Decision Flow — Which Heating Element Should You Choose?

In the case of gloves, flex with carbon fiber; in jackets, even with film, in socks/insoles, thin with film, and in cost-key items like vest, wire.

Step 4 — Choosing Fabrics and Insulation Materials

The envelope is made of fabrics and insulation and logic makes sure that the fabric and insulation are breathable, protective, and that the fabric and insulation are trapping heat but not impeding movement.

Outer Shell Fabrics

Smoothy stretch jackets: softshell, vests, polyester light, gloves, weather pants: nylon.

Skinskin jackets and leather gloves respectively gave freedom to skiers and workers.

Waterproof/Windproof Membranes

TPU jacket breathable, PU pants strong against gloves -IPX4+ snow.

TPU prevented wind chill in riding projects.

Insulation Layers

Thinsulate thin/warm with jackets, cotton basic, but absorbent with vests, fleece soft with socks and down substitutes lofty with pants.

Thinsulate used in clothing kept the hunters warm without making their gloves too thick.

Lining Fabrics

Mesh jackets, brushed fleece coat-of-arms gloves, wicking allows in the socks.

Working pants were kept dry by wicking lining.

Heat Retention vs Mobility Trade-Offs

Thicker has more advantage, but has limitations–thin Thinsulate to use active, fleece to use statical.

Sweat was not collected in ski jackets because of balance.

Application-Based Fabric Choice

Skiing: Waterproof softshell + Thinsulate; hunting: Silent nylon + fleece; workwear: Leather + Thinsulate; riding: Windproof softshell + wicking.

Step 5 — Choosing the Right Components & Accessories

The system is linked by components and usability and Safety logic.

Switch & Controller Types

Button fit vests, waterproof jackets, remote gloves, App smart jackets.

Hunting vests had remotes that made silent adjustments.

Wiring Harness & Connectors

Flexible wiring bend, safety insulated connectors.

Strong in work trousers withstood tears.

Zippers & Fasteners

Jackets have waterproof zippers, gloves have anti-snag.

Vests with a magnetic aid were useful.

Battery Pocket Design

Safety ergonomic sealed pockets.

Low in jackets for balance.

Step 6 — Ensuring Component Compatibility (The Most Overlooked Step)

Check matches: A high volt of strong components prevents overheat; heavy textiles require considerable amount of heat penetration; hard wires impede gloves; non-waterproof-switches are not effective in snow. Incompatible insulation muted heat in a pant project, and the layers needed to be thinner.

Step 7 — Practical Examples (Scenario-Based Recommendations)

For Skiing

7.4V battery, extreme, all weather fabrics, carbon fiber- fast thaw lifts.

For Hunting

5V battery, middle, noisy fabrics, film–sly coziness.

For Outdoor Work

12 volt battery, constant operation, high-quality leather, wire–high economical life.

For Urban Everyday Use

USB 5-volt, low plus, light polyester, film–portable light heat.

Step 8 — Common Mistakes When Selecting Components

Voltage wrong makes heat weaker; bad elements make it hot, bad fabrics result in leaks, low-cost batteries are not certified, and disregarded wiring disconnects.

Final Recommendation — How to Make the Best Component Choices

Coordinate battery-heating-fabric:{To hold required voltage power(voltage to elements) insulation to retain. A priority to safety-certified components. Activity accordingly: Intense when skiing, Balanced when hunting. test to confirm – success is achieved through integrated systems.