Introduction — Why Testing Heated Apparel Before Mass Production Is Critical

When it comes to the apparel sector, which is experiencing a hot season, your brand is betting with its branding to neglect the extensive pre-production testing. A QC engineer in OEM factories with more than ten years of experience in electric heating product manufacturing, I have observed personally how untested equipment results in battery malfunctions, inadequately heated items or even hazards in the field. The safety test of warm clothes is not negotiable as the items are a combination of electronics, batteries, and fabrics any defect in the products may lead to overheating, short-circuiting, or to ineffective heating in severe cold conditions. Adequate testing of pre-production heated gear will easily identify problems at an early stage, making sure that the battery is reliable, the heating is consistent and meets international standards, which will cost less than losing money in a faulty recall or rework in the mass production.

The Essential Tests Every Heated Apparel Product Must Pass

Begin with the fundamental tests that have a direct influence on safety and functionality- these are your make-or-buy tests prior to giving any prototype the green light to scale.

Battery Safety Test (The Most Important)

Not a single piece of heated apparel reaches the production process without undergoing battery test on heated apparel. Start with overcharge and discharge testing: Charge the battery to 120 percent of capacity and observe by BMS (Battery Management System) shutdown; discharge to 0V and ensure that there is no leakage/no swelling. Then, perform short-circuit tests, or other words, test the faults using a low-resistance wire, the pack must be able to take fault through the protection circuits immediately without igniting. Thermal stability tests are performed by putting the battery in an oven at 60degC during cycling and ensure that they do not blow up or deform. Lastly, confirm UN38.3 requirements by vibration, shock and altitude testing because the lithium-ion transport requires. In my factory work experience, these failures have stopped the whole lines to prevent field fires.

Heating Performance Test

The best part of the testing of heated clothes is checking the output of the system. Let temperature rise to full power (goal 45-60degC in areas, but without going beyond safe skin-contact limits (55degC max by IEC standards). Test heating rate, time, ambient-target temp- time goal 2-5 minutes on quality elements. The procedures of heating uniformity test involve probes on panels to make sure the difference does not exceed 5degC to eliminate hot spots. Finally, stability of check temperature during use by charging at moderately high temperature during 4 hours, flexing the garment, ensuring that no drops are lower than 40degC. I have managed tests that have had to be redesigned due to poor uniformity, spared the client the problem of customers complaining of cold patches.

Wiring & Connector Safety Test

Wires and plugs experience continuous motion, thus test bending: Test the connector to 3,000-5,000 90 degree bends, checking cracks or resistance spikes. Use pull tests on connectors with a force of 10-20N of 1 minute to ensure no disconnections occur. These discourage failures in use, such as those which occur when skiing. During production shifts, I have spotted frayed wiring before it could cause any short that could melt fabrics.

Waterproof & Moisture-Resistance Test (IPX)

In the outdoor apparel, waterproof and IPX are essential tests of the apparel that has been heated. Submerge or spray samples to IPX4-IPX7 standards- e.g. IPX4 to splash resistance in jackets, post exposure testing of electronics is no shorts. The IPX6 is commonly used with gloves and socks in heavy rain simulation. Blow down and retest heating to ensure that no moisture is entering. In factory conditions, it is found that by omitting this, corroded circuits are obtained in damp conditions.

Secondary but Necessary Tests for Higher Quality Assurance

After passing primaries, apply these to enhance durability and long-performance and transform your product into quality and high quality.

Fabric & Material Durability Test

Test the tear resistance of the outer shell of the garment with an Elmendorf machine at 20-50N depending on cloth material. Abrasion tests are conducted on sample 1,000 times against sand paper to test wear. Stretch impact tests stretch material 50 percent at a time, eliminating delaminated heating elements. These are simulated in the real world snags or pulls as I have tried them out in working lines where hard snags could never allow early failure.

Flex Test for Heating Elements

Testing of heating elements Durability Tests: Body joints Fold 5,000 times, resistance stability (less than 5 percent change). This mimics everyday use, which is essential to bendable carbon fiber or graphene films. Poor flex testing has also led to disruptions in the heated pants when using squats in my consultations.

Thermal Cycling Test

Perform thermal cycling five to ten thermal cycles of heating to maximum temperature and cooling to ambient temperature, with observation of degradation. This discloses the defects in glues or solder joints that should guarantee an extended life span of the product beyond 500 charge cycles.

Battery Runtime Verification Test

Specs should not be relied upon, battery runtime check: discharge at every level: Low-4-6 should be 8-10 hours on a 5,000mAh pack, medium-high should be 2-4 hours on that pack. To consider cold induced loss of capacity (20-30% decrease), test in 0degC chambers. Actual factory information tends to revise designs to be more efficient.

Step-by-Step Pre-Production Testing Process (PPS Flow)

Use this guided process of testing the workflow of these structured heated apparel in order to go through the design-to-production process smoothly.

Step 1 — Inspect Heating Elements

Check size (size usually visually and electrically checked), resistance (usually 5-20 ohms), and uniformity with a multimeter. Any with 10% variance should be rejected in order to eliminate hotspots.

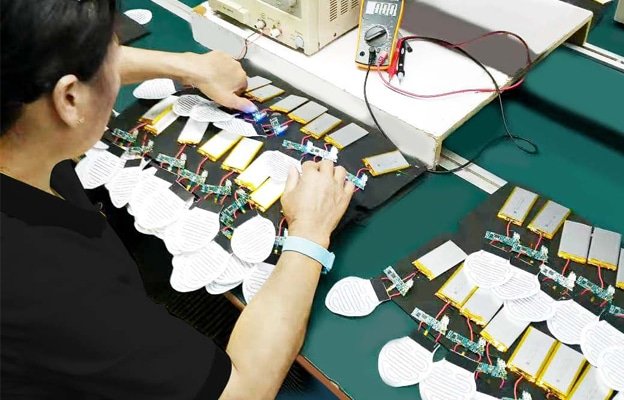

Step 2 — Inspect Battery & BMS Board

Check battery protection circuit: Check Overheat protection at 70degC, overvoltage shutdown at 4.2V/ cell, and short-circuit protection. Waveforms analysis with oscilloscopes.

Step 3 — Conduct Prototype Thermal Test

Build a prototype and run a thermal performance test of warm-up clothes, with temperature sensors to map temperatures and over test temperature accuracy within +-2 degrees centigrade of set points.

Step 4 — Assemble Pre-Production Sample (PPS)

Assemble final materials in units (3-5) and perform initial QC (fit and wiring integrity).

Step 5 — Functional Test

Test all levels (low/medium/high), check the indicators of LED lights, and even heat distribution.

Step 6 — Stress Test

Simulate use: Wear-test 8 hours to include bending and moisture exposure, in order to simulate field conditions.

Step 7 — Approve PPS or Revise

Check data; when the failure rates are below 5, redesign and retest must be done before mass approval.

Category-Specific Testing Requirements

Test specifically to garment type to achieve specific reliability.

Heated Jackets & Vests

Attention to large area uniformity of heat back/chest and battery pocket pull testing to 50N. Make sure there is no under weight.

Heated Gloves

Heated glove testing procedures involve single finger heating tests, which involve a test of uniformity to fingertips (usually 35-45degC) and flex tests as a measure of dexterity.

Heated Socks & Insoles

Consider moisture-resistance and IPX5 immersion and flex capabilities of at least 10,000 steps when foot compression is required.

Heated Pants

Test thigh + knee heat distribution, to be smooth over leg bends with additional abrasion tests to high wear areas.

Testing Equipment Commonly Used in Factories

These tools are needed to equip your QC lab with in order to obtain accurate, reproducible results.

Thermal Imaging Camera

Capture heat displays heat maps to display uniformity- needed to identify cold spots in real time.

Temperature Probes / Thermocouple Sensors

To obtain a precise measurement, put K-type probes at several points recording values with time.

Battery Analyzer

Compare charge/discharge curves, capacity and efficiency at different loads.

Tensile Testing Machine

Measure the connector pull strength, and pull at 1mm/min to failure.

Flex Endurance Equipment

Automatically bend 3K-5K cycles with resistance checks added after the test.

OEM Perspective — Why Proper Testing Reduces Cost & Risk

As a consultant OEM, I have recommended the factories where testing, with test robustness, has reduced defects by 15 to less than 2 percent.

Reduces Mass-Production Failure Rates

The number of reworks reduces as early catches increase yields and profits.

Ensures Compliance Certification Success

Passing CE, FCC, RoHS, and UN38.3 the first time, without delays and penalties.

Customer Satisfaction & Brand Reputation

Dependable heat reduces returns, which creates trust, I have seen brands increase sales 2x after certification.

Common Testing Mistakes Factories Make

Don’t make these traps that I have rectified in audits.

Only Testing Heat Level, Not Heat Stability

Long-term runs are not common in factories, and drops are experienced after 2 hours.

Ignoring Wiring Durability

Negligence of bending tests results in field breaks.

Not Testing Battery Load Behavior

Under lab conditions; invariably take low-temp tests.

Skipping Waterproof Testing

Vital to outdoor gears but is usually ignored until complaints come by.

Testing Only 1 Sample Instead of Multiple PPS Units

Variability requires 3-5 samples of stats.

Final Recommendations — How Buyers Should Test Before Approving Mass Production

Sourcing by the buyer: Empower it.

Always Request a Full Test Report

Transparency in demand with detailed logs containing photos and data.

Verify Real Runtime on All Heat Levels

Demand specification matching lab verification.

Use a Thermal Camera to Validate Heating Zones

Test consistency internally or externally.

Perform Bend Tests on Heating Wires

Wear should be simulated to guarantee durability.

Test Battery at Low Temperatures (0°C to –10°C)

Assure no sharp impaired ability during wintery seasons.

To sum up, it is important to learn the possibility to check heated jackets prior to their mass production and analogues by means of systematic QC of heated apparel which will help to turn possible risks into trustworthy products. By focusing on these tests, you will provide apparel that is safe, effective, and market-ready – it is based on my experience in factory floors and provides the basis of successful partnership in OEM.